The production and maintenance of quartz burners was causing some trouble. That's why Philips decided to redesign the burners, with the help of Sirris' expertise in additive manufacturing.

Since 2013 Sirris is organising an annual master class on ‘Design for additive manufacturing’. During this training participants learn all the tricks of the trade to design products in function of 3D printing. This is a very hands-on workshop during which all knowledge gained is immediately applied to a company-specific case. At one of the previous master classes Philips developed a redesign for a quartz burner.

The burner is used to heat quartz. Four burners are set up at each machine position to heat several positions. When the quartz is sufficiently heated, it is squeezed tight by means of squeeze blocks to make sure it becomes gas-tight.

The old burners were made from a copper alloy - to ensure proper cooling and because it allowed for brazing. However, the holes caused when the cooling channel was drilled, had to be closed.

Leaks

The production of these burners met with quite some problems: it is not easy to make the drill holes watertight by means of brazing. When the first drill hole was soldered and the technician would start on the second one, the first one would start to leak again because of the heat needed to solder the second one properly. When heating quartz, a lot of quartz fumes are released which are then deposited in cold places (for cooled burners). This meant the burners had to be cleaned (sandblasted) very often, which also caused the burners to leak.

Efficient redesign

That is why Philips designers attended the master class organised by Sirris' AM experts. Before the redesign, only the existing burner and not the entire burner set-up was modified.

In the redesign process the cooling channel was placed in the most optimal position and Philips used inconel as an alternative material, which has the property of absorbing fewer quartz vapours.

The places where O-rings were to be installed required post-processing to ensure that the burners would not leak there. Then tests were carried out and temperatures measured.

After two years there is still no need to replace the new burners. Cleaning requires no more than simply blow them clean with compressed air. This is definitely a successful redesign!

Do you want to know if additive manufacturing can be an interesting option for your production or product? Visit us at Prototyping 2017, where you can see the redesign of the burner for yourself!

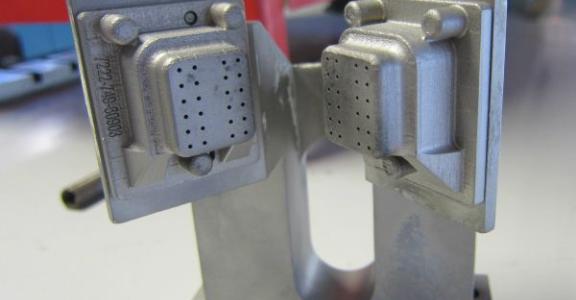

Old burner

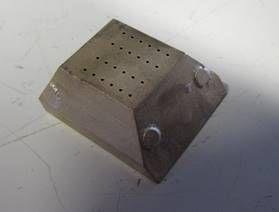

Old burner on the machine with a great deal of quartz deposit

The new burners assembled and cleaned

The new burners in action