Almost 10 years after the introduction of cryogenic machining, a lot of research has been conducted on this technology, its application and pros and cons. However, despite the positive results, the step to the industry does not seem to be so obvious. High time to present this interesting machining method in detail in a short blog series, of which this is the first one.

In 2011, cryogenic machining was introduced at the EMO trade fair in Hanover. Emulsion was replaced by liquid nitrogen at temperatures of around -190 °C. The considerable cooling capacity was definitely a big advantage when machining heat-resistant materials, for example, where temperatures can reach 1,000 °C. These high temperatures have a heavy impact on tool wear. In the meantime, a lot of research has been carried out on the potential advantages and disadvantages of cryogenic machining.

Gas used

Liquid nitrogen is not the only and most commonly used refrigerant gas in Europe. In addition to nitrogen, CO2 is increasingly emerging as a usable gas. According to the literal definition, this is not a cryogenic gas (<-100 °C), but in the machining world it is often classified as such. When CO2 is used, the cooling occurs differently, namely through expansion. The gas is contained in the cylinders under high pressure (up to 50 bar) and as soon as it expands - and therefore leaves the nozzle or tool channel - it will fall back to very cold temperatures. Nitrogen has a greater cooling capacity, but the temperature is less stable. The disadvantage of nitrogen is that the components have to be able to cope with the low temperatures. After all, there is a risk that parts that move over each other will freeze. With CO2, there’s the high pressure to be coped with, without losing gas in the process.

Application and benefits

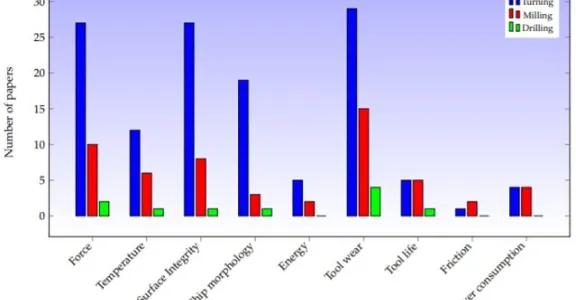

This technology is still applied primarily to heat-resistant and hard materials. A lot of studies have been carried out on titanium alloys in particular. A recent overview paper - ‘Sustainable Lubrication Methods for the Machining of Titanium Alloys: An Overview’ - summarised this research tendency. Publications have increased considerably in recent years and are by far the most viewed of all cooling methods (MQL, dry machining, etc.).

With these materials, the main focus is on what temperature control does to the process properties. The most frequently mentioned benefits are reduced tool wear (up to 50 percent), better surface quality (lower roughness, less residual stresses) and better chip formation (less adhesion). This overview also shows that the friction aspect has not yet been studied a lot. However, this is also a parameter that should not be underestimated in machining. The latter is sometimes improved by a combination of MQL (oil droplets) and cryogenic gases, where the oil droplets improve lubrication.

Not only the cooling aspect can be advantageous, cryogenic cooling also offers other advantages, including making the workpiece more brittle in order to obtain better chip formation and the ecological aspect. These themes will be discussed in more detail in two subsequent blogs.

Technology

For cryogenic machining, the machine needs certain modifications. It’s not just about connecting a cooling tank to the existing pipes. There are two options to do this: on the one hand there are ready-made machines with integrated cooling on the market. In the nitrogen range, the American 5ME is the world leader, for CO2 Fusion Coolant has a patented system on the market. These manufacturers allow integration into existing machines. At the EMO 2019 in Hannover, Willemin-Macodel presented itself as a partner company, which can supply these machines.

On the other hand, the technology can also be built on existing machines. This requires some more re-engineering. Gas suppliers take care of the supply of the refrigerant and can also provide a monitoring device that can be controlled with free M codes in the CNC programs. In this way the supply can be automated.

Installation in turning processes is relatively easy, as the tool does not rotate and the cooling can therefore be properly directed. In case of milling or drilling, this is a bit more complex. For this purpose - depending on the application - it may be interesting to work via internal cooling channels, but this means that you must be able supply the coolant to the tool via the spindle or tool holder. Sirris developed a prototype toolholder that makes this possible for CO2. In case of external cooling (during milling this may be sufficient) it is important to direct the cooling to make sure the cutting edge is reached.

Price

The solutions that were devised for this purpose on existing machines are rather limited in terms of price and machine-independence. The gas itself is a consumable (unlike an emulsion, it cannot be reused), but for materials that are difficult to process, the tool cost is often so high that it is certainly compensated by the gain in tool life. A ‘cleaning’ step can often also be omitted, as this is a neutral and clean gas.

In the industry

In the United States, the technology has already made its breakthrough, as demonstrated by the technology suppliers who developed the solutions. In Europe, the first factories are starting to equip themselves with cryogenic cooling. Also in Belgium, several interesting cases have already been studied and turned out to be positive. Larger research projects in cooperation with machine and tool manufacturers are also underway in several European countries. Sirris will continue to work on and develop this, so that Belgian industry is not left behind.

Would you like to discover whether this technology is interesting for your application? Feel free to contact us !

Source

2019, Sustainable Lubrication Methods for the Machining of Titanium Alloys: An Overview, Enrique García-Martínez, University of Castilla-La Mancha, Albacete, Spanje