Interreg Fabricar3v | democratizing metal additive manufacturing

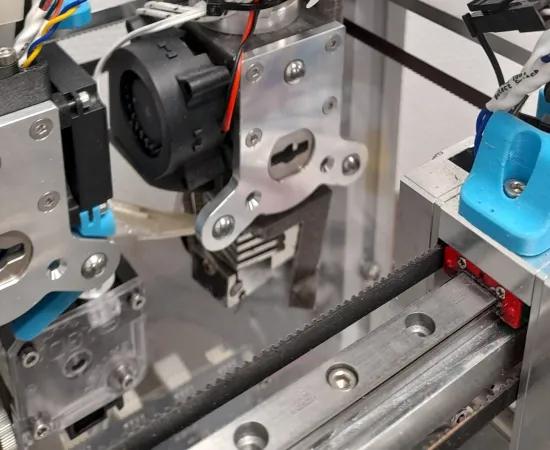

This project aims to democratize metal additive manufacturing by setting up a low-cost material extrusion machine (FDM) able to handle metal injection moulding (MIM) pellet feedstock. The final goal is to make everything (machine manufacturing drawing, procedures,…) open source afterwards, and in this way accessible for everyone. To improve knowledge dissemination, a platform will be set up and a process simulation tool will be developed.

Context

Nowadays, it is difficult to find an AM machine, making metal parts at a cost lower than 100 k€. This is prohibitive for quite a lot of companies and others, such as educational organisations.

Objectives

- To develop a material extrusion AM machine able to handle MIM feedstock (SS 316L polyMIM) at a cost lower than 30 k€

- To compare the part properties (surface quality, mechanical properties,…) of the machine prototype developed to other metal-based AM technologies (such as laser beam melting)

- To set up a research platform to share knowledge on and experience in AM

- To develop a process simulation tool

- Quantify the impact of AM large dissemination on the intellectual property

Approach

A machine prototype will be developed. PolyMIM 316L feedstock will be tested on it and parts will be characterized at each steps (green, debound & sintered). A cost analysis will be performed.

Identical parts will be made and characterized on laser beam melting of 316L powder, for comparison purposes. A technological watch will also be performed to extend the comparison.

Techno watch will also be performed on business models of similar low-cost technologies and IP issues linked to AM.

A research training platform will be set up to share experience and knowledge at large scale (trainings, machine manufacturing plans, data,…)

The technology will be compared to other metal AM technologies (parts properties, costs) and a process simulation tool will be developed.

Target group

SMEs, schools, universities, fablabs,… and similar organisations.

Reference

Interreg Fabricar3v 1.1.362

Project partners

Belgium:

- Cenaero

- Sirris

- Université de Mons

- FLAM3D

France:

- CNRS

- CRITT-MDTS

- Ecole Centrale de Lille

- Machine 3D

- Université de Lille