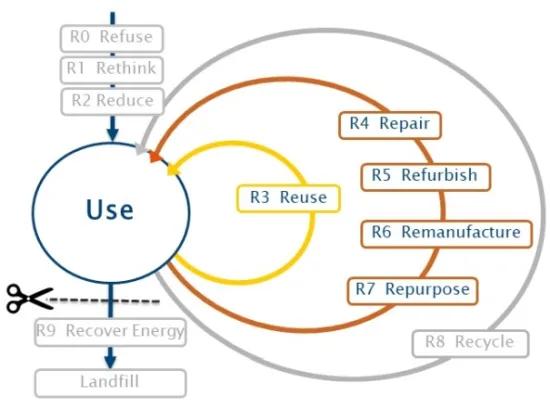

The circular economy is more than just recycling. Reuse, repair, upgrading, remanufacturing and repurposing indeed offers great potential for preserving the value and reducing the environmental impact of products. The inner circles of the circular economy have long remained under the radar. Manufacturing companies also tend to struggle with the complexity of exploring these options, including with how to put it all into practice. A new project has now come to their rescue.

The Circle project is ready for the challenge of supporting manufacturing companies in exploring the circular strategies of reuse, repair, refurbish, remanufacture and repurpose. To make it simple, we will use 'remanufacturing' as the collective name for all the inner circles.

Many companies indicate that they are open to initiatives or that they see a potential for additional activities, while they still encounter many challenges of a practical or business nature. Remanufacturing encompasses a wide range of different business models and ways of retaining value, including remanufacturing to original level, remanufacturing to upgraded level, remanufacturing in a product service system, reuse of remanufactured parts, remanufacturing services ... Each model has its own characteristics, value chain perspective and technological competences. Additionally, there is the need for useful information which facilitates setting up an efficient remanufacturing process.

The challenges are numerous: business model and value chain, organisation of remanufacturing operations, choice of supporting technology for these operations, product suitability, customer needs and acceptance, information management throughout the chain, return logistics, etc.

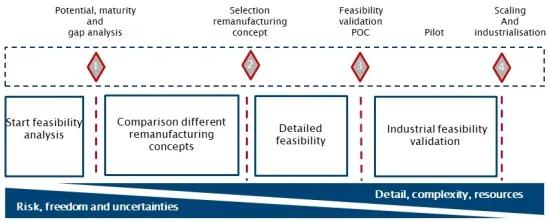

In short, it is a complex matter which could definitely do with some sort of step-by-step plan tailored to SMEs, aimed at exploring opportunities while gradually identifying and reducing risks.

Circle project to the rescue

In this project, we will provide companies with a pragmatic, step-by-step approach which gives them tools they can use according to their specific context and needs. Needs are different for different products, different remanufacturing strategies, place in the value chain, previous knowledge and experience with remanufacturing activities ... The tools are validated on the basis of a few concrete cases. We also identify key technologies to support remanufacturing for SMEs, including inspection, dismantling and disassembly, repair, reassembly and the associated quality and safety management.

Big steps forward

The first months of the project, which we are about the launch, will focus on gaining insights, on key criteria for estimating the potential and feasibility of remanufacturing. We will build a casebook, identify a number of typical remanufacturing types and compare their distinguishing features. Based on this, we draw up a simplified diagram of remanufacturing types and their characteristics and critical success factors. This will enable SMEs to quickly detect the most successful avenues from a wide range of options and to explore them in a targeted manner.

Interested in this topic?

Make sure to let us know! In this way, we can also share the knowledge we have gained with your company. We are at the beginning of this two-year process and will therefore be able to regularly use your input to set up the approach and supporting tools in such a way that they really work for SMEs.

This means for you that you will receive more information and insight into the progress on a regular basis. Do you already have questions, needs or suggestions regarding remanufacturing? Feel free to contact us!

More information on the Circle project can be found (soon) on the project page (under construction)

(Source edited picture: https://www.dreamstime.com)