The paradox of planning

Planning tools often generate high expectations. Many production companies dream of improved planning. With improved planning, one typically hopes to bring the hectic work floor under control, achieve shorter lead times and deliver more accurately. In this blog you will read why even the most advanced planning tools often disappoint, and how you can deal with their shortcomings.

In order to solve the planning problems, many companies have invested in planning tools. The first generation of planning tools typically planned for infinite capacity, making it very difficult to make realistic planning. Modern planning tools do take capacity limitations and plans against finite capacity into account. Despite the intelligence of these modern planning tools, making a realistic planning remains a difficult task. How come? Why is it still so difficult to make a reliable planning?

System Dynamics

In order to understand this, some insight in to system dynamics (the science of the behavior of production systems) is necessary. Planning tools are typically used to predict when an order will be ready, in other words: planning is ultimately about predicting the lead times in a production system, but what determines the lead time?

The most important factor that influences the lead time is the occupancy rate. The occupancy rate is the percentage of the time for which work is available at a workstation. An occupancy rate of 80% therefore means that work is available for 80% of the time and that there are no orders for 20% of the time.

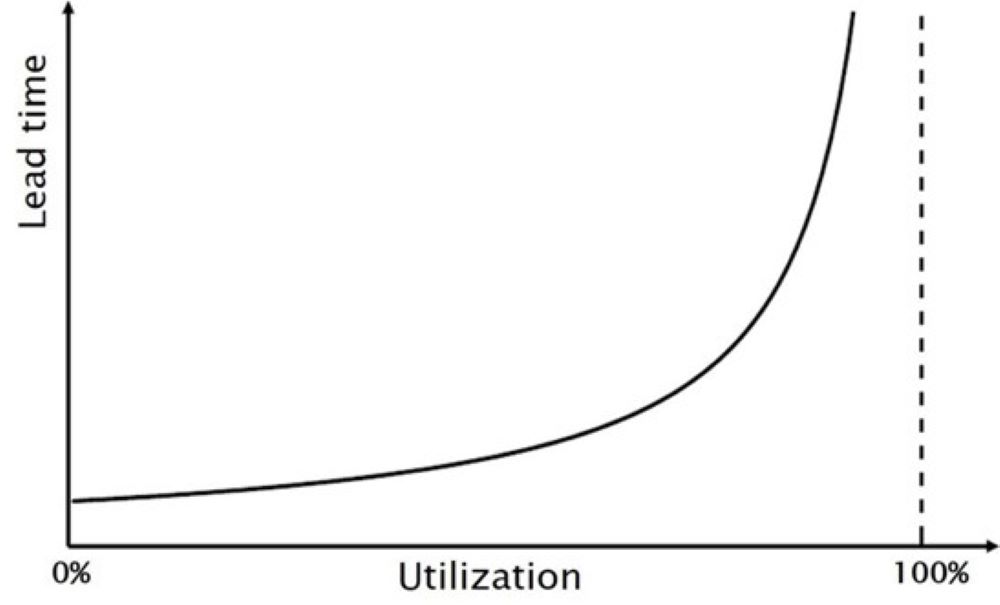

The relationship between the occupancy rate and lead time is shown in the figure below:

As can be intuitively expected, the lead time increases with increasing occupancy. The busier it is, the longer everything takes. However, what is peculiar is that the lead time suddenly starts to rise sharply as soon as the occupancy rate hits approx. 80%. For example, the lead time with an occupancy rate of 95% is approximately four times as long as a lead time with an occupancy rate of 80%.

The strong influence of a high occupancy rate on the lead time implies that even small errors in the time estimation of the orders can have a major impact on the lead time. Since time estimations can easily have a margin of error of 5 to 10%, it is therefore no surprise that an accurate prediction of the lead time is difficult.

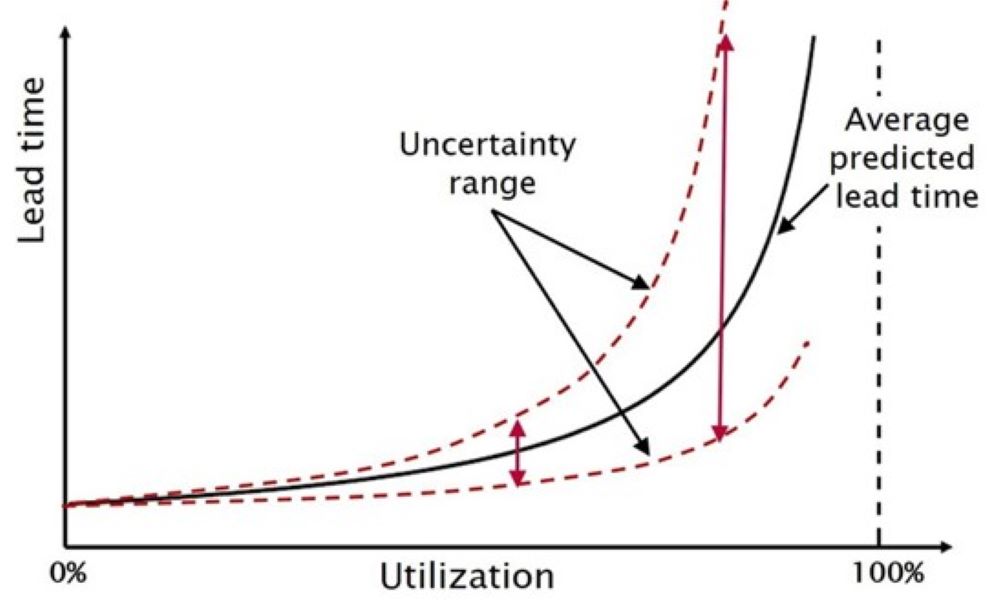

A second effect that complicates planning is the effect of variability. Two types of variability have an influence on the planning. On one hand there is the process variability. These are the unpredictable variations in the duration of a production run as a result of breakdowns, extra rework, absences, etc. On the other hand, there is the variability in the arrivals of the orders at a workstation. These are the unpredictable variations as a result of upstream problems such as late deliveries, material problems, amendments, etc. Due to these two forms of variability, an interval of uncertainty arises on the predicted lead time, which also becomes stronger as the occupancy rate is higher (see figure below). This interval of uncertainty on the lead time prevents accurate predictions from being made.

Paradox of planning

These observations now lead to an interesting paradox. Companies that have long and highly variable lead times feel the most need for a ‘good’ planning system. These long and highly variable lead times are typically caused by a high occupancy rate. However, the lead times in systems with a high capacity utilization are hardly predictable due to the effects mentioned above, making planning ever so difficult. This leads to the planning paradox: when the need for a planning system is highest, planning tools will perform the least.

The weather system offers an interesting analogy. People who live in a stable climate (e.g. a dry climate) generally feel little need to follow the weather forecasts. The weather is pretty much the same on a daily basis. People who live in an unsteady climate have the greatest need for weather forecasts. However, it’s the unstable climates that are difficult to predict due to their chaotic nature. Short-term predictions are often successful, but predictions that are slightly further in time are often very unreliable.

Solutions

A way out of this planning paradox is improving the production system itself by reducing the lead times. Short lead times require less planning and are generally also more predictable. By working on reducing and stabilizing the lead times first, the ideal conditions will be created in which a planning tool can work well.

Fortunately, there are powerful solutions available in order to shorten the lead times. For example, Quick Response Manufacturing (QRM) is a production strategy that focuses on improving production by shortening lead times. Quick response manufacturing concentrates on the more complex environments (high-mix-low-volume) in which planning is often a difficult task.

Learn more?

In spring 2024, we will organise a new course on quick response manufacturing. This QRM Silver course will give you a deeper understanding of QRM and will include testimonials from business leaders, various case studies and QRM simulation games. Keep an eye on our aganda for this or contact us!