Machine tool performance - Part 1

While recent technological advancements have created a high demand for parts and components of increased precision with tighter tolerances and functionalities, the complex nature of machine tool performance makes it difficult to see what causes deviations or errors in final part quality. To produce parts with the required accuracy, the relationship between machine tool characteristics and part accuracy and surface finish must be evaluated, in order to control deviations within required tolerances. In-depth knowledge of the machine performance is a must.

A machine tool is a very complex system consisting of hundreds of mechanical and electronical components that interact and function together to produce parts with the required shape and dimensions withing certain tolerances. The complex nature of this system makes it very difficult to analyse the cause and effect of machine tool degradations and the resulting deviations or errors that may occur in the final part quality. However, technological advancements in recent years have created a high demand for parts and components of increased precision with tighter tolerances and functionalities. To produce parts with required accuracy, the relationship between the machine tool characteristics (physical attributes) and part accuracy/surface finish must be evaluated, in order to control deviations within required tolerances. Achieving that level of accuracy requires having deep knowledge of the machine performance, in order to achieve such precise and repeatable positioning.

Accuracy vs. precision

Before we dive deeper, let us look into the basic definitions of accuracy and precision.

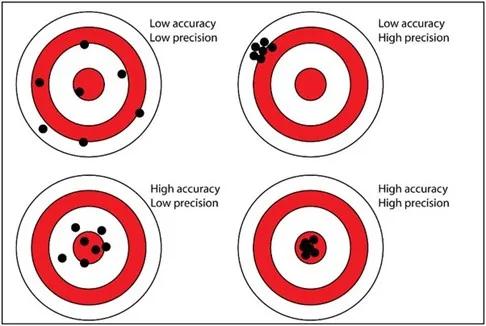

Accuracy: By definition, accuracy is the closeness of agreement between a measured quantity and a true value of a measurand. In terms of machining, it is the ability of the CNC machine to execute an operation the way its NC code was intended. Accuracy is a qualitative description and sometimes is referred to as “error.” In this sense, a machine tool can be said to be more accurate when the deviation between nominal and the actual position is smaller.

Precision: Precision (also referred to as 'repeatability') is defined as the closeness of agreement between the successive measurements of the same quantity or result of an operation carried out under the same conditions. In context of a machine tool, it is the error between several attempts to move the machine to the same position under the same specified conditions.

This is illustrated in the figure below.

Difference between accuracy and precision

Machine tool performance and errors

To measure the performance of a machine tools, we need to continuously measure and quantify its functional ability. The functional ability is characterized by the variations in the performance as function of the physical attributes’ geometric, kinematic, static, dynamic and thermal behaviour of the machine tool. In other words, its ability to withstand or maintain any deviations of the actual cutting point from the nominal or commanded position or trajectory at different physical conditions. These deviations are the errors that can arise during the functioning of a machine tool. To make sure the machine tool is performing at an optimum level, these errors should be under control.

It is important to understand these errors and their sources to be able to evaluate the machine tools performance. Machine tool errors can be classified into two categories: (i) the quasi-static types, which are slowly varying in time and are related to the machine tool structure physical attributes and characteristics (geometry, thermal behaviour and stiffness), and (ii) dynamic errors, which depend on operating conditions of the machine tool (feed speeds, accelerations, jerk, spindle motion), process-related vibrations and chatter, and dynamic stability. We will look into these errors in depth in the forthcoming article .

Would you like to learn more about machine tool performance and find tools to implement this knowledge on your shop floor? You can attend our workshop on stainless steel machining on 16 November 2023, where you can learn hands-on about practical tools based on analytical physical models, developed to help you choose optimum conditions for your machining processes. In our agenda, you can find more information about the workshop and register.

For any further questions please do not hesitate to contact us.