The use of femtosecond lasers for laser marking, instead of the classical nano- and picosecond lasers can prevent corrosion. Unknown is unloved and therefore Sirris gives you the opportunity not only to get acquainted with this new laser technology, but also to compare it with the technology you have in-house.

Laser markings are subject to corrosion. The heat from today's nano- and picosecond lasers changes the material around the marking. This heat affected zone (HAZ) is susceptible to corrosion, often even after passivation. By optimising your laser parameters, you can limit this HAZ.

A potentially better solution is to use a laser that does not heat the material or heats it less: femtosecond lasers. The pulse duration is reduced by a factor of 1,000 to 1 million. The intensity of the pulse has become so high that the material does not get the chance to melt or heat up. Femtosecond lasers are currently undergoing the same price evolution as previous laser technologies (CO2, nano, pico) and will therefore soon be within everyone's reach. After all, a CO2 cutting laser or nanogravure laser are already commonplace. A femtosecond texturing laser at your company is certainly a possibility.

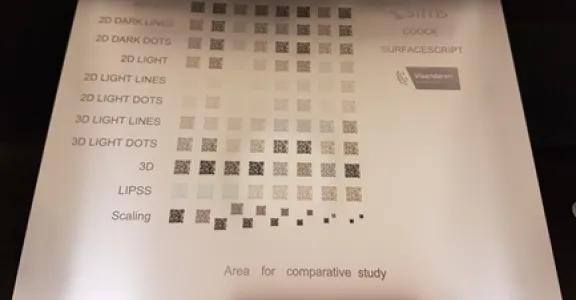

In order to introduce you to the potential of femtosecond lasers, Sirris offers you the opportunity to gain a first experience. On material that you provide (a 15 x 20 cm plate), we make a laser marking according to a defined pattern. Within this pattern, space is also provided for you to mark with your own laser. In consultation, Sirris performs a standardised passivation and salt spray corrosion test and compares the markings made by the two lasers.

This blog has been written within the framework of the COOCK Surfacescript project.

Picture above: Example of a stainless steel (1.4310) test sheet, dimensions 15 x 20 cm and thickness 300 µm

Source: https://www.kleinmetals.ch