In order to support their customers even better and to allow them to test the impact of different technologies on their end product, Spiromatic set up a test bakery and accompanying laboratory. This is where the bakery expert scientifically analysed the product and the production process which will allow them to give advice about required improvements. To this effect, the company recently developed a software tool for breadcrumb analysis.

East Flanders-based Spiromatic specialises in total solutions for artisanal and industrial bakeries, in particular for the storage, transport, conditioning, dosing and mixing of dry and liquid raw materials. The company relies on a great deal of in-house knowledge izefor the design and implementation of custom processes and automatic dosing of raw materials for bakery products. The company wanted to gain a better insight in the mixing and baking processes, and the machine settings used by customers.

Responding to an evolving market and production

Processes are increasingly being automated, also for bakery products. Because the transition to automated solutions changes the way ingredients are handled, this could have an impact on the quality of the dough and end product. It is therefore crucial to properly analyse the effect of each step on the final product. In addition to taste and crust, the crumb structure also appears to be important to consumers. This structure depends on numerous factors, which makes an objective and scientific measurement method essential to correctly analyse industrial baking processes.

Spiromatic also wanted to respond to the market trend of consumers preferring to switch to more natural products. The use of preferment, such as sourdough, is a response to this market trend. The company wants to assist their customers with the necessary knowledge in choosing dough as a fully-fledged alternative to other bread improvers (the so-called E-numbers). Most customers still use E numbers, but their application is under pressure.

Keeping knowledge up to date

The final evaluation of product and process is typically based on baked bread. No objective unambiguous method exists yet for intermediate products. The assessment is usually visual and based on feeling (the elasticity of the dough, for example, is evaluated by stretching it), sometimes on the basis of the sound of the mixer and sometimes by means of tests.

In order to perfect its knowledge, Spiromatic started an on-site test bakery in 2018 as an R&D room for the production of preferment and (sourdough) bread. In this flexible and quickly configurable bakery, the company intends to find out how preferment dough can be optimised. Small-scale tests can be used to determine the effect of preferment on the baked products. In addition, Spiromatic’s research department wants to study the possibility of transforming the process to an industrial scale. Both small companies and large bakeries can go there for advice and infrastructure in relation to the production of sourdough and other dough products and learn how to give certain properties to the bread, such as a dense or just a light crumb structure. Spiromatic can also help these customers with the development of recipes for preferment. Thanks to the trial bakery, customers can be sure that the desired result will be achieved. Spiromatic is now offering a new service and a new product (equipment for the production of preferment).

All facets of the production process of sourdough bread must therefore be performed and assessed on a small scale in the test bakery, while also making various types of preferment, which can be further optimised by experimentation. In addition, it will also be possible to determine the effect of the preferment dough on baked products and thus optimise it. In this way, the improved recipes can be more easily translated to the production infrastructure (to be realised) at the customers with the same results as in the test bakery. Finally, the company also wanted to make the process in the test bakery controlled and predictable. For this, both a clear goal and the influencing parameters had to be known, measurable, the measurement data processed and the results visualised. It also had to be possible to adjust and optimise the process digitally.

Analysis tool

The first step was to monitor the sourdough process itself. This is done on the basis of five parameters: time, temperature, pH, TTA (acidity) and fermentation strength. Spiromatic provided the experimental bakery with the necessary infrastructure and measuring equipment for this purpose.

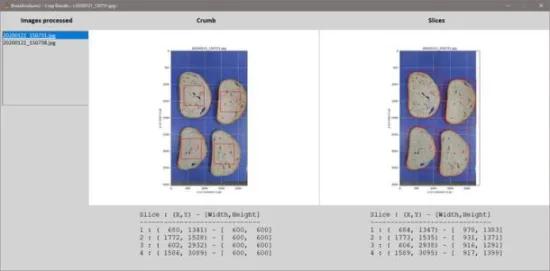

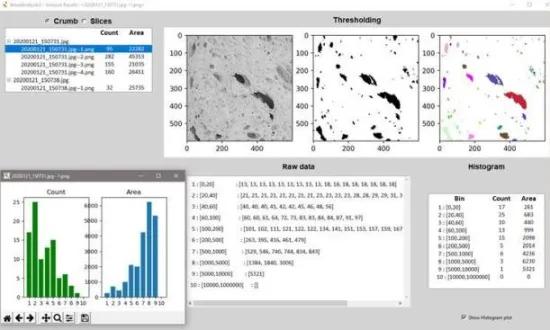

In a second step, the focus was on substantiating the advice given to customers. It must be possible to analyse the bread after baking. An important parameter, for example, is the crumb. Cuts of bread produced according to a specific process with a specific flour and sourdough are analysed for the number and size of gas cells and holes in the crumb. After all, these make the difference between a light and a compact loaf of bread. This was done using the new 'Breadcrumb Analyser' software, with which the parameters can be set to perform an analysis on photos of the bread slices. For the development of this software, Spiromatic appealed to Sirris and the University of Ghent, Faculty of Bio-engineering Sciences. Sirris used research results from UGent as a basis for the development of a specific software program, in which the analysis results are presented in an Excel file. Depending on how the parameters are set, the analysis will be different. The software has been adapted in such a way that different types of bread can be analysed.

Sirris provided an easy-to-use interface and added the option to adjust the parameters, automatically pour the results into Excel files and visually display them in columns, diagrams and even on the footage itself. This makes it easier for users to draw the right conclusions when using, for example, a certain type of flour, sourdough, etc. Once the development was validated by Spiromatic, the know-how was transferred to the company so that the company can now use its own experts to work with it and expand as required.

Thanks to the Breadcrumb Analyser, Spiromatic's customers can now scientifically evaluate and compare their products in the test phase, and estimate the impact of even the smallest change of ingredient on the structure. This makes it easier to make adjustments to the recipe or the production process until the desired final quality is achieved.

(Source picture above: Spiromatic)