After a qualification campaign, Sirris has obtained Airbus APWorks certification and has joined the international network of Scalmalloy® users. This high-performance alloy can now be tested by companies.

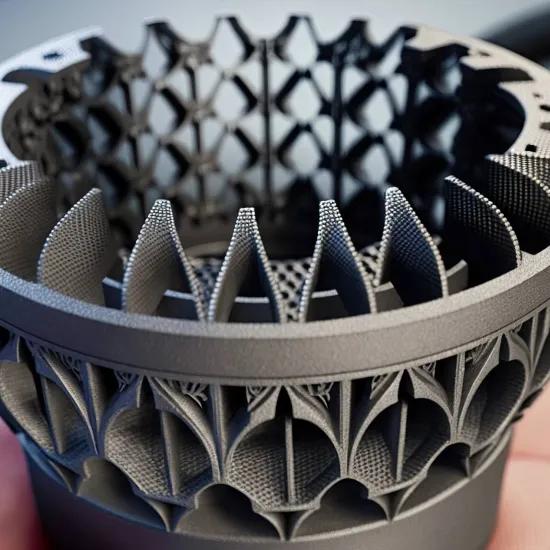

Scalmalloy® is a light aluminium – magnesium – scandium alloy specifically developed for additive manufacturing by Airbus APWorks. It is implemented by selective laser melting and is characterised by a particular microstructure which proffers it with excellent mechanical characteristics.

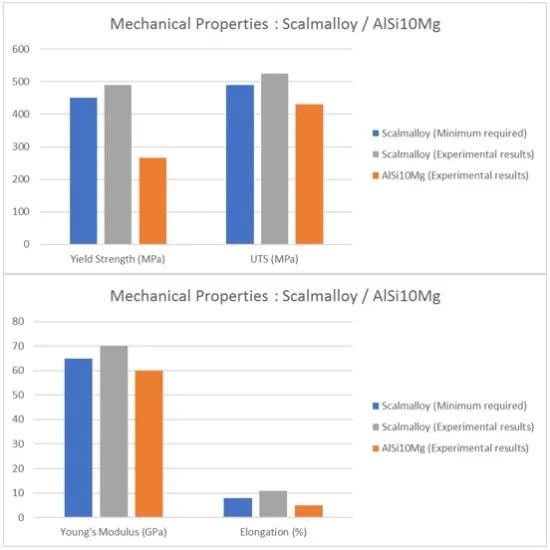

These properties largely exceed those of conventional alloys such as AlSi10Mg, as indicated in the technical specifications.

We note an 80% increase in the elastic limit, 20% in breaking strength and 120% in ductility, in equivalent manufacturing conditions as for AISi10Mg.

These excellent results are even exceeded thanks to certain thermal post-processing techniques applied at Sirris.

Over and above these results, the alloy offers an excellent aptitude for welding, good resistance to corrosion, a low thermal expansion coefficient and a stable microstructure up to 250°C.

Sirris is proud to become a certified Scalmalloy user and to be able to offer new possibilities to companies looking to produce aluminium parts. A vast range of sectors are concerned, from the aeronautical to the automotive industry, via robotics and sports equipment.

Belgian industrialists will be offered the opportunity to benefit from this new material, which further diversifies the range of additive manufacturing materials evaluated by Sirris.