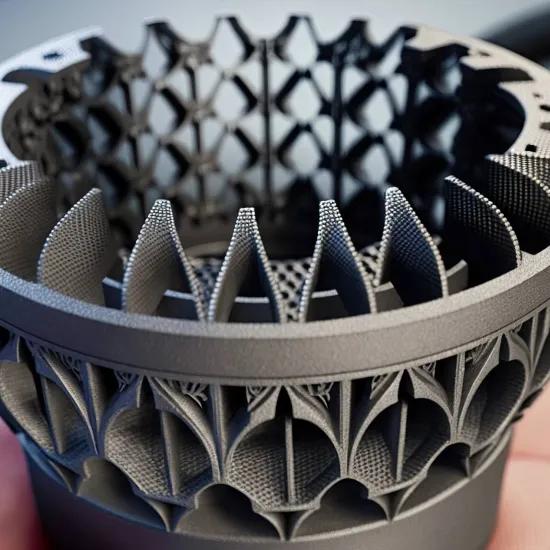

The quality of the powders used in additive manufacturing is crucial for achieving good parts. It is the subject of discussions in the standardisation committees.

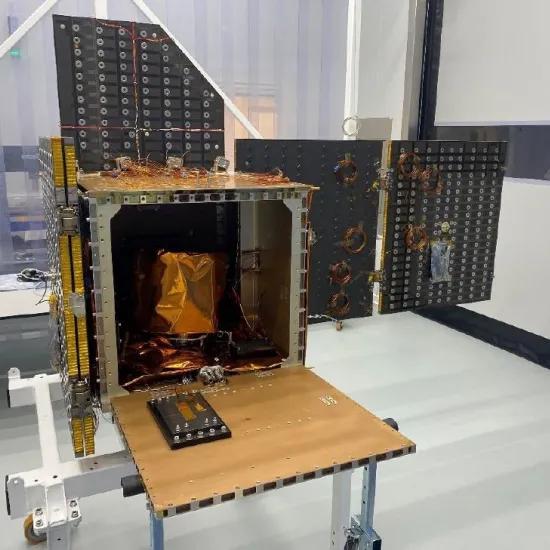

The quality of the powders dedicated to additive manufacturing, especially in metals, is currently at the centre of discussions in the Technical Committees for AM standardisation. Indeed, the integration of additive technologies into industry requires better control of these technologies, guaranteeing their reliability and reproducibility. Advanced sectors, like aeronautics and space, have been asking for this for many years.

Several standards specific to AM have been published in recent years by the ISO, CEN and ASTM, in particular relating to nomenclature and general principles. However to ensure the reliability of the technologies and the reproducibility of the manufactured parts, the industry requires standards directed towards the processes, defining working methods that guarantee a final result. And the quality of the materials used in the process is also as crucial as the machine settings selected for production.

Several standards have been published or are still in preparation for metal powders:

AFNOR XP E67-010: Poudres - spécifications techniques (Powders – technical specifications)

ASTM F3049-14: Characterizing Properties of Metal Powders

ISO/ASTM NP 52907: Additive Manufacturing - Technical specifications on metal powders

ISO/ASTM DIS 52911-1: Additive manufacturing - Technical Design Guideline for Powder Bed Fusion - Part 1 - Laser-based Powder Bed Fusion of Metals

They set out a series of powder characteristics and properties which should be noted, as well as references to the existing standards specifying the analysis methods for these properties. Unfortunately, they are not sorted in terms of the relevance of these characteristics in relation to the process in question. All the characteristics of a given alloy powder may or may not be significant for this or that process.

The preparation of standards directed towards the repeatability of the processes is work that requires excellent knowledge and mastery of these processes. Many trials and tests are still needed in order to support the discussions of the Technical Committees, leading to relevant standardisation. For a year now, Sirris has been working on a pre-standardising project examining the most relevant characteristics of aluminium alloy powders intended for the LBM process, and their effects on the properties of the final manufactured parts. The main deliverable of this project will be a methodology for the acceptance, storage and recycling of these powders, based on measuring the changes of certain properties like particle size distribution, the level of humidity and oxidation. Acceptable ranges of values will be defined. Another deliverable is searching for an analysis technique of a powder characteristic (flowability, packed density, etc.) enabling the rapid detection of any drift of these properties, whose origin can be determined subsequently. The final results will be sent to the AM Technical Committees and can help in the preparation of specific material standards.

If you would like more information about this project or about additive manufacturing standardisation, please contact us through our Standards Cell.