Hygi Panel has taken on the challenge of increasing its production by a factor of four in just five years. To achieve this, the company set up a Made Different programme. This exercise mapped out the main challenges and identified the steps needed to improve the production process while ensuring impeccable quality.

Hygi Panel, based in Fernelmont, has more than 30 years of specialised experience in the development, manufacture and installation of complete wall and ceiling cladding solutions that have to meet the strictest sanitary and maintenance standards. To ensure its future, however, the company decided to focus exclusively on sustainable innovation. It set itself the goal of drastically increasing production volumes within a time frame of only five years. This was a challenge, especially given Hygi Panel’s rather traditional production processes. Hygi Panel intended to scale up by constructing a new building and buying new machines. It then got together with Sirris to see whether this was actually the best solution.

Brainstorming the best solutions

Under the guidance of Sirris, the entire production process was thoroughly analysed to see which optimisations and innovations would be needed to scale up production sustainably. For example, the current production steps - from buying raw materials to customising the products - were analysed to see how they could be better organised and further industrialised. When comparing options, their effects on the well-being of the employees - and not just performance and productivity - were considered. Hygi Panel deliberately chose to involve the employees in this exercise by way of coordination, training, etc., and to communicate frequently about the progress.

The result was a concept that made a new building unnecessary as it fitted perfectly into the existing one. The medium- and long-term social and environmental impacts, in terms of reducing emissions, were also taken into account.

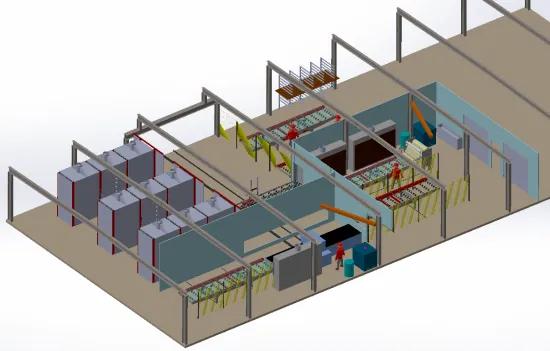

| Actual workshop | Final 3D-study |

Feasibility study and action plan

To give further shape to the concept, a collaboration was set up with the SPW EER (Wallonia Public Service for Employment, Research and the Economy). A feasibility study was begun to address the outstanding challenges, which included:

A detailed study of the individual production processes and production steps

Analysis of the production cycle showed that excessively long polymerisation times caused a bottleneck. In collaboration with external parties and suppliers, this was eliminated by using a new recipe to change the polymerisation process.

From traditional to industrial

An investigation was made into how the various processes could be industrialised. This was done by a technology search and, where necessary, by building (small) proofs-of-concept with technology suppliers to evaluate certain options, such as automating the movement of products. (The latter, incidentally, also makes the work more ‘workable’ by reducing the burden on the operators.)

An ecological-technological breakthrough

Finally, alternatives to polyester - or better ways to reuse it - were considered in order to move towards a circular economy. To do this, various ecological solutions were inventoried to see how far the production concept, as developed, could be used to process these new materials.

The feasibility study could then be used to identify potential risks for each option. Hygi Panel is currently looking for local industrial partners for this project in order to complete the planned investments by the end of 2023.

|