Belgium is one of the pioneers of additive manufacturing (also known as AM or 3D printing) and, as such, already benefits from a well-developed ecosystem that is ideal for experimenting in the field. Hence, all the conditions are reunited so that you too can reap the benefits of these technologies. All you need is a little helping hand to find out how.

Additive manufacturing (3D printing) has been around for years. Yet the industrial sector remains relatively unfamiliar with it, hence missing a great number of practical applications towards progress. Belgium is among the technology’s pioneers and offers an ecosystem that is already highly developed and extremely propitious to experimentation in the field. So, all the conditions are reunited so that you too can reap the benefits of these technologies.

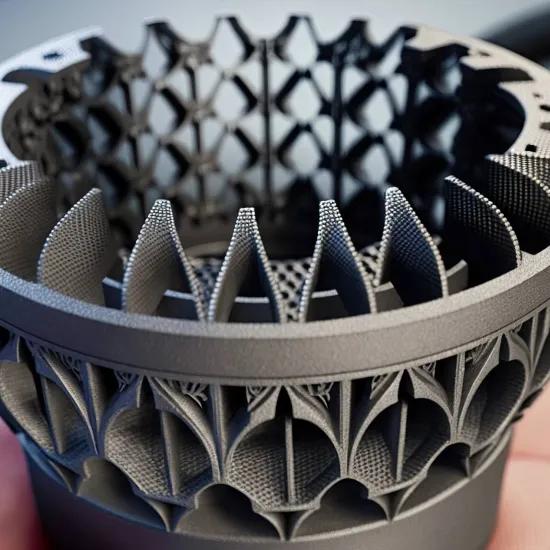

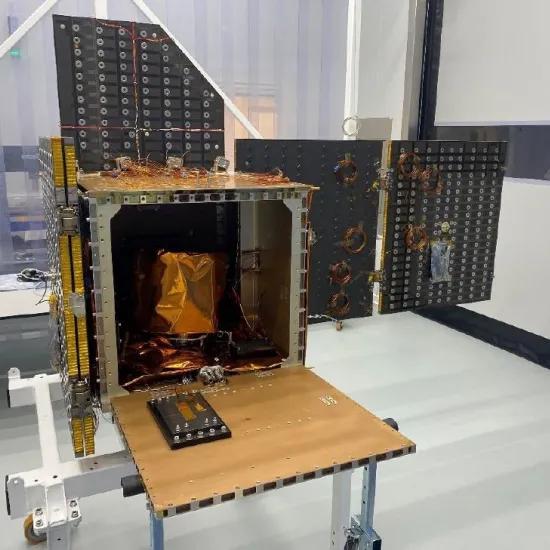

Additive manufacturing can be implemented in all sectors, not only those that appear obvious. Of course, we already produce titanium or PEEK implants, lightweight structural components for the aerospace sector, optimised electronic boxes or miniaturised heat exchangers for the automotive industry. But AM doesn’t end with product parts. The entire tooling chain, in the largest sense, can also prove to be a sometimes underestimated source of profit. The most striking example is, of course, that of plastic injection moulds with controlled temperature distribution, hence shorter cycle times. We can also find all the necessary tooling to accelerate assembly line operations or to facilitate continuous part conformity during machining. And, in more subtle terms, certain processes or production lines present non-optimised elements that could benefit from enhancement to ensure improved productivity/quality. For example, moving parts that present excessive inertia, hence slowing down production pace, or pressure drops that generate vibrations, hence deteriorating precision or provoking premature wear of the production tool.

All these examples demonstrate the scope of AM potential. There may also be potential applications for your own business, allowing you to optimise, accelerate or render increasingly profitable your manufacturing or machining processes. Even if they are not immediately obvious. This is why we are proposing the masterclass entitled: ‘Integrate 3D printing in your business’, to be held on 13 April 2022. The perfect opportunity for you to familiarise yourself with 3D printing and, in particular, to identify its possible scope within your company.

The aim of the masterclass will be to cast light on the great potential of AM, whilst identifying the traps you want to avoid. Several inspiring examples will be shared, and you will benefit from personalised discussions in response to your specific questions. You will be guided in the right direction, at the right pace. So that your business can move into second gear… or 3D.

This programme is part of Industriepartnershap in which 17 Flemish innovation partners offer an integrated service to stimulate growth and innovation in the Flemish industry in the 3 following themes: Digitisation, Sustainability & Industry 4.0. They do so under the leadership of Agoria and Sirris and with the support of Agentschap Innoveren & Ondernemen.