Belgium is the fourth most productive country in the world, but our productivity growth has been sputtering. In this series we present four tips each time to boost productivity in the office and on the shop floor.

In the first part of this series we discussed the productivity of Belgian companies. Productivity growth in our country has been underwhelming in recent years and this is unfortunate because productivity growth allows us to work less hard.

In order to support Belgian companies with their productivity improvements, we collected a number of tips that we will publish at regular intervals. These tips are deliberately focused on improvements that require little effort and pay off quickly.

Tip 43: Use your head first, not your wallet

Productivity is the relation between output and inputs. The inputs include the hours worked and also the investments made. The less investment needed to solve a problem, the higher the productivity. Unfortunately, it often turns out to be easier to come up with a complex, expensive solution than a simple one. Coming up with a simple solution requires some creativity.

We recently received a request from a company that was looking for a solution for the automatic removal of paint hooks in a painting line. An obvious approach would have been to immediately look at automating the existing manual working method. This would have led to a complex system involving a camera system to detect the hooks and a robot to grasp and remove them. But a simpler solution was possible. The insertion of a curved rod into the flow of paint hooks proved sufficient to solve the problem. The video below shows how the paint hooks gently collide with the curved rod and briefly follow its curvature; they then tilt, which causes them to come unhooked and fall into a waiting container like ripe fruit.

What can we learn from this? Always look for simple, elegant solutions first and avoid unnecessarily expensive solutions. Or, as Taiichi Ohno, the founder of the Toyota production system, used to snarl at his staff when they came up with complex solutions: use your head first, not your wallet.

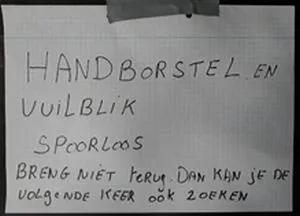

Tip 44: Eliminate searching: give everything a place and put everything in its place

Maybe this should have been the first tip in the series. It is the most obvious one, but at the same time the most difficult one to keep.

The best known method for ensuring order in the workplace is '5S'. This method summarises common sense in five steps: Sort (= remove all clutter first), Set in order (= give everything a place), Shine, Standardise (= make clear agreements), and Sustain.

In itself, this method is not surprising. We have all learned it in one form or another at nursery school, where learning to tidy up is one of the educational objectives.

It is best not to rely too much on self-discipline to maintain order. So arrange your workplaces in such a way that it is easier to be orderly than disorderly. This starts with giving everything a unique place (so not one slide for all keys, but one place for each key). Clearly mark out these places (e.g. with tape) and label each one. A practical way to do this is by using shadow boards, or cut-out inlay foam in the sliders. That way, you can also see what is missing.

You can also block off the space that you do not need so that it cannot be used for other purposes. This can be done by putting empty boxes in unused places in cupboards, sloping shelves on top of cupboards or by adding shading.

The video below shows how productivity in a workshop increased by giving everything a unique place.

Tip 45: Improve welding specifications and avoid unnecessary welding

Welding is often the bottleneck in manufacturing companies and welders are a bottleneck profession. Increasing the productivity of welders can therefore have a big impact. The first step in increasing the productivity of welders is to determine exactly which weld is to be applied. Product designers sometimes have insufficient knowledge of the welding process and will therefore over-specify, specify an unnecessarily difficult weld or not include enough welding information in the drawing. In the latter case, the welder chooses the welding joint, but this will therefore not be the best choice.

The productivity of welders can be greatly increased by limiting the welding volume. Limiting the welding volume also reduces problems with warping. Ask yourself whether it is necessary to weld a piece over the entire length. Perhaps a few welding stripes or a chain weld will suffice. In addition to the length of the welds, limiting the throat height (A-height) of the weld is also decisive for productivity. If the throat height is high, several weld beads have to be applied.

Finishing the weld is a time-consuming activity. The welds that are not visible in the final product often do not require post-processing. Also indicate this on the drawings. Also evaluate the set tolerances at the weld. If the weld has close tolerances, the welder will have to check and adjust more often.

The use of the appropriate welding symbols (according to standard EN ISO 2553:2019) on the drawings is essential for good communication between designers and welders. Ask your welders about the quality of the drawings. Is the type of weld, the quality level (fillet weld, chain weld, through-weld) and the finish on the drawing? Is it clear where welding is not allowed? Your welders may also have ideas on how the welding work can be improved by a product modification (e.g. better location of welds to avoid deformation, different type of material, etc.). In short, organise a meeting between the designers and the welding department and provide the necessary training for your product designers about the welding process (see also Tip 2).

Questions about welding? Sirris members are automatically also members of the Belgian Institute for Welding Technology (BIL) and can obtain free welding advice. You can also contact the BIL for training, for example on welding symbols.

Tip 46: Limit the number of late customer changes

Late changes to an order by the customer often cause additional work and stress for employees. Therefore, try to limit the number of late changes. By improving communication with the customer, you can avoid wasting a lot of time.

Start by looking at your sales process. Did the salesperson properly identify the customer's requirements or were there blind spots? Did they leave any unnecessary openings for changes in order to get the order in quickly? If necessary, wait to enter the order until all data are known. (See also Tip 8 on improving the information)

After ordering, you can use the order confirmation to discourage changes. Let the customer know that you have just started working on his order and that any changes will incur additional (administration) costs. Inform the customer that the delivery time can only be guaranteed if there are no more changes, or even more clearly, inform the customer that in the event of any change, the delivery time will expire.

Finally

Do you have any tips to share? Let us know so that we can share them and become more productive together! The best tipster gets a nice gift!

Click here for an overview of the other parts in the series.

(Source pictures: https://www.pexels.com)

]]>