Belgium is the fourth most productive country in the world, but our productivity growth has been sputtering. In this series we present some practical tips each time to boost productivity in the office and on the shop floor.

In the first part of this series we discussed the productivity of Belgian companies. Productivity growth in our country has almost come to a standstill in recent years. Based on the productivity figures, the fourth industrial revolution does not seem to be delivering the hoped-for results. If we cannot reverse this trend, we will be doomed to work longer and longer.

In order to support Belgian companies with their productivity improvements, we collect a number of tips that we will publish at regular intervals. During our company visits, we see that there is still a lot of low-hanging fruit to be picked. These tips are therefore not only aimed at implementing advanced technologies, but at improvements that can be achieved with relatively little effort.

Tip 71: Optimise your price setting

(Source: https://www.pexels.com)

The pricing of your products directly determines your added value (= sales - purchases), and thus your productivity (= added value / working hours). As purchases often make up a large part of turnover, a small price increase can have a major impact on productivity and profitability. For example, if purchases account for two thirds of the turnover, a 1% increase in price will immediately lead to a 3% increase in productivity. Correct price setting is therefore a lever for optimising your business. Despite the importance of price setting, we see that many companies do not think this through. Tracking costs often gets more attention than finding out the right price.

Several signs are indicative of prices that are too low and should encourage you to experiment with price increases:

- Demand is higher than your production capacity. Some people mistakenly believe that there is a shortage of labour, but the law of supply and demand dictates that the wrong kind of pricing inevitably leads to an imbalance in supply and demand. The scarcity in the labour market is not ‘the problem’, it is simply the solution to the unemployment problem.

- Customers rarely complain about the price, or indeed, you lose few tenders because of the price.

- You are cheaper than your competitors without good reason, or you offer clear added value compared to your competitors for a similar price.

- You haven’t adjusted the price for quite a long time; your price setting is lagging behind inflation.

- Your price is based on the cost and not on the value of your product.

- Your profit margin is very low.

Raising prices can be a sensitive issue. There may be a fear of losing customers. There are various tactics to deal with this:

- Ask new customers a higher price first.

- Test price increases on a small proportion of your customers. If the majority of the customer accepts the price increases, you can extend them to the other customers.

- Do not give a discount immediately if a customer asks for it; lower the discount percentages.

- Differentiate prices more according to the value of your product or service to the customer. For example, a service contract has a higher value for a customer whose machinery runs continuously. Some customers will also be willing to pay more for a shorter delivery time.

- Make the customer pay for free services too.

- Combine the price increase with something extra for the customer that hardly affects your costs. For example, you can offer a longer warranty period at the same time, if you have few warranty costs.

- First raise prices on the most popular part of your product range. This part is apparently the most sought-after, so it is possible that customers will also be willing to pay a higher price.

- For those customers who do not accept a price increase, you can offer an alternative product with a lower value at the old price. You can also negotiate different payment terms, less service or a longer delivery period with these customers in exchange for the old price.

There is a chance that by asking a higher price you may lose a few customers, but this is not a bad thing. Dare to ask yourself whether these price-sensitive customers are a good fit for your business. Another source of resistance to price increases may be the company's own sales staff. Consider, therefore, linking the sales staff's bonuses no longer to their turnover, but to the margin achieved.

Tip 72: Improve the layout

In a survey by Sirris, 30 per cent of respondents said that the current layout has a negative impact on production efficiency. New machines and workstations are placed where there is space, without regard to optimal flow and walking distances. Redesigning the layout therefore offers great potential for saving time. A good starting point is often to make a ‘spaghetti diagram’ in which you draw out the movements of people and materials. This will quickly give you an idea of possible layout improvements. It may not be possible to find a good layout for all flows. Therefore, when rearranging, focus on the main flows first.

Simplified spaghetti diagrams with indication of main and secondary flows

(Source: Sirris)

You can find more tips on how to improve your layout here.

Tip 73: Balance the work with bucket brigades

Many tasks are done by a group of people who have to work together. In such situations, a loss of productivity can occur when the work is not properly balanced among the different people. A number of techniques can help to balance the work better (see also tip 59).

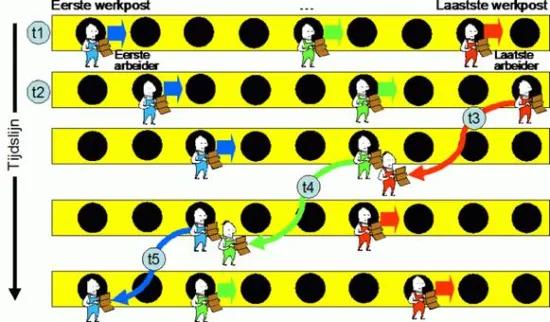

‘Bucket brigades’ are self-organising systems that are ideal for the coordination of workers in a production line with more workstations than workers. The operation of bucket brigades is illustrated by the figure below. A bucket brigade distributes the workers to the workstations (time 1). As soon as a worker finishes his operations at a workstation, he walks to the next workstation (t2). When the last worker at the end of the line finishes a product (t3), he goes back and takes over the work of the last but one in the line. This one in turn goes back and takes over the work of his predecessor (t4). This continues until the first worker is relieved, after which the first worker can start a new product at the beginning of the line (t5).

Workers cannot be overtaken on the line in bucket brigades. If a worker does catch up with the next operator, he must wait until the next work position becomes vacant. To avoid this, the workers should preferably be arranged on the line according to their work speed. The slowest worker will take first place, while the fastest worker will take last place.

The workers in a bucket brigade are thus not restricted to a fixed set of workstations; they have to finish each product to the greatest possible extent. Since all the operators are working all the time, the line is perfectly balanced and thus the output is maximum. In conventional production lines, the typically uneven distribution of work will create an imbalance that will cause some operators to have to wait frequently.

Bucket brigades have several attractive features:

- The rules of the game are simple and the same for every worker. So there can be no confusion about the tasks to be performed. In fact, line managers no longer need to actively intervene to distribute resources across the line.

- The line can balance itself, making detailed time studies in the design of the line unnecessary. It is also no longer the slowest employee who sets the pace on the line.

- Bucket brigades are an ideal way to integrate new, slower workers into the production process effectively without creating bottlenecks. Moreover, the greater the speed difference among the workers, the stronger the line will tend to balance and the better the system will remain balanced.

Besides applications in production, bucket brigades are also frequently used to balance the workload among pickers in distribution warehouses. The traditional way of dividing the work is to divide the warehouse into zones and assign a picker to each zone.

The problem with such zone picking is that the work is not necessarily balanced. If we replace the division into zones with a bucket brigade, we can achieve a balanced distribution of work. The impact of bucket brigades cannot be underestimated. One distribution centre already reported a 30 per cent increase in the number of picks per person due to the switch to bucket brigades. More information on bucket brigades can be found here.

Tip 74: Set the temperature in the office to 21-22 °C

In office environments, the temperature is sometimes a point of discussion. For some it is too cold, while for others it is too hot. We even know of a company where the thermostats were switched during installation. When it got a bit too hot in one room, the temperature was turned down a bit, but because of the switch, the neighbouring room would cool down, which caused the occupants to get cold and turn up the temperature, causing the temperature to rise further in their neighbouring room... As a result, one group was sweating more and more, while the other was shivering.

What is in fact the impact of temperature on productivity? Numerous experiments have already been set up to answer this question. A meta-study summarised the results in the figure below. The study showed that the optimum temperature is about 21-22 ⁰C. As soon as the temperature exceeds approx. 25 ⁰C, a drop in productivity of approx. two per cent per degree becomes noticeable. For example, at a temperature of 30 ⁰C, productivity is 9 per cent lower than at the optimum temperature.

Relationship between productivity and temperature

(Source: Seppänen, 2006)

But what about the cost of maintaining the temperature? Well, the wage cost of office workers is typically a factor 100 higher than the energy cost of a building, so a small improvement in productivity can quickly be earned back. For example, one study estimated that the cost of lost productivity is seven times higher than the cost of energy. The investment in better air conditioning is typically earned back within two years.

Finally

Do you have any tips to share? Let us know so that we can share them and become more productive together! The best tipster gets a nice gift! We would like to thank Jaap van Ede and Federico Brinchilin for their inspiration.

You can find an overview of the other parts of this series with tips here.