Sanding away remnants of runners and risers with a cobot

The Hassal foundry was looking at using automation for sanding away burrs and the remains of runners and risers on castings - a dirty, dangerous and repetitive job. Although automating this work comes with some challenges, it was thought that these could be met by using a cobot. The company, working together with Sirris within the COBOFIN project, put this to the test.

In the COOCK project COBOFIN, some generic finishing cases were looked at to see if it would be feasible for cobots to perform the sanding or deburring processes. The last two cases of the project concerned the machining of castings. We will explain each of these feasibility studies in separate articles. In this article, we will take a closer look at the case of the Hassal company.

Hassal is a family business specialising in the static casting of high-quality aluminium products. The company is based in Hasselt and, with more than 50 years of experience in casting processes, is regarded as an expert in the sector. They have their own mould-making plant and use the most efficient casting techniques to guarantee high-quality aluminium castings. They also offer finishing activities such as tumbling, drilling, thread tapping, turning or milling, up to and including assembly and custom packaging. The products that Hassal makes can be found in a whole range of applications, from outdoor lighting and street furniture to machine building.

'Dirty, dangerous, dull'

As with most casting processes, static casting typically involves unwanted burrs that must be removed in a finishing step. The aluminium in the runners and risers that remains attached to the product after de-moulding must also be removed. In the first step, most of this is sawn off. The burrs and the remnants of the runners and risers are then removed manually by sanding. Because this is ergonomically demanding, dirty and monotonous work, for which it is increasingly difficult to find personnel who can do it with the necessary care, Hassal wants to investigate how the operators can be assisted through semi-automation with a cobot.

Flanges were chosen as test pieces for the COBOFIN project. This was because of their potential to save working time, the large numbers in which they are produced and the repetitive nature of the work. Moreover, this involves relatively boring, monotonous and unpleasant manual work performed with the risk of injury from a coarse sanding belt.

Challenging operation

The work consists of sanding the flange circumference after removing the sprues, in order to remove the burrs (flashes) from the casting and sanding the outer edge evenly so that the marks from sanding away the sprues are no longer visible.

The case involved some specific challenges: the runners and risers are first removed on a sawing machine, leaving stumps of varying lengths. Those stumps must then be sanded down to the outer edge of the flange. Furthermore is the sanding of the circumference sensitive to stoppages or changes in the speed of the robot - the slightest stoppage causes a dent due to the metal being sanded away.

Testing strategies

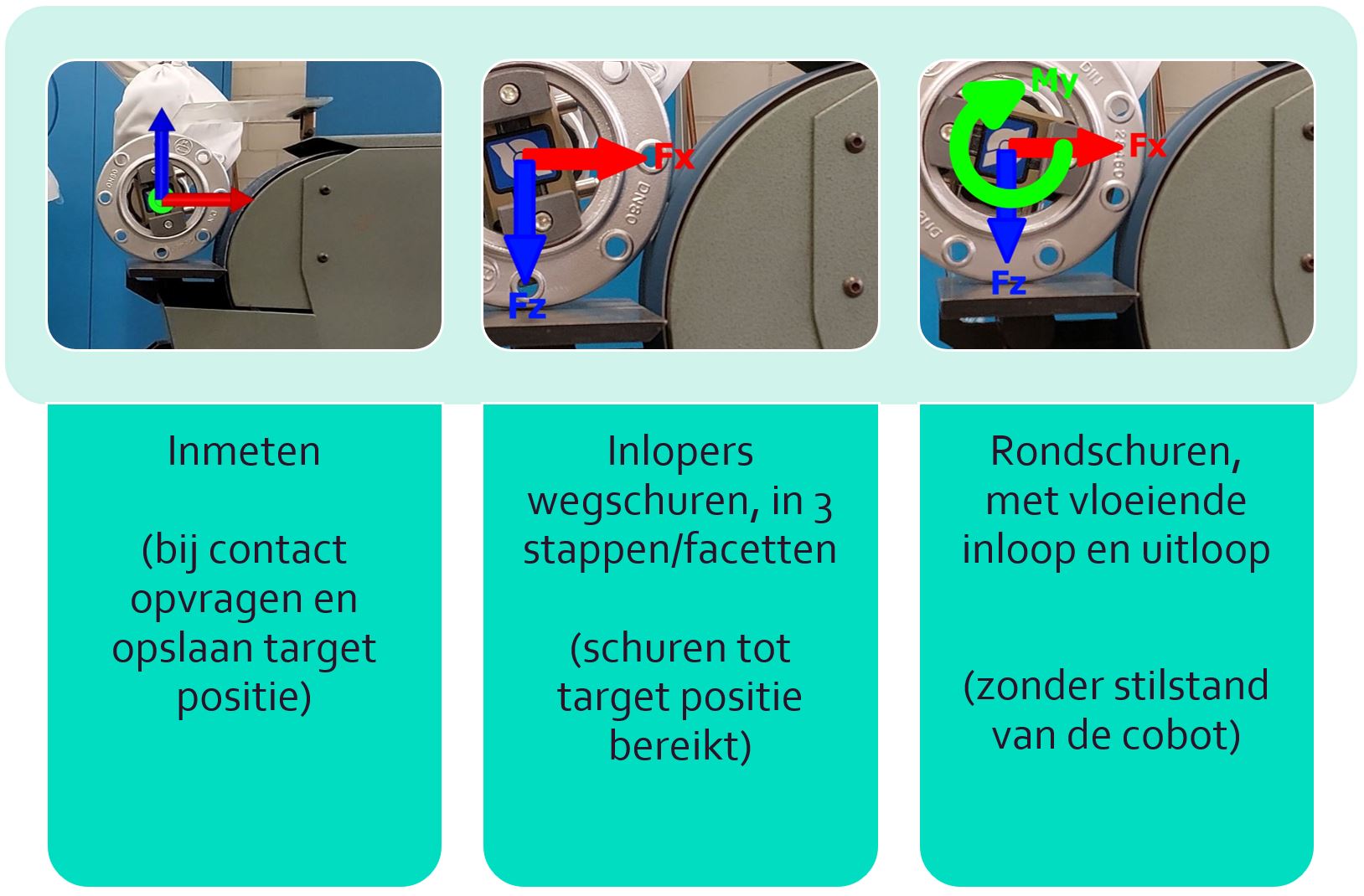

To address these challenges, several strategies were tested. The first strategy was to sand away the remains of runners and risers (of unknown length) up to the outer edge of the flange. This was done by having the cobot measure the target position from an already-machined flange and save this as a reference. To remove as much of the sprue as possible, each sprue mark was sanded to this reference size on three facets. The flange is pressed against the sanding belt by the robot with a preset force until the target position is reached.

A second strategy tested involved sanding off the burrs on the outside edge by sanding the entire circumference of the flange without halting the robot. This is done by making the robot move according to the forces involved instead of the usual method of programming the robot to stop at spatial positions.

Because these tests convinced Hassal that there was potential in this, they went on to carry out initial tests for other products. This puts cobot sanding high on Hassal's innovation agenda.

|

Coock-COBOFIN was enabled by support from VLAIO (Flanders Innovation & Entrepreneurship).