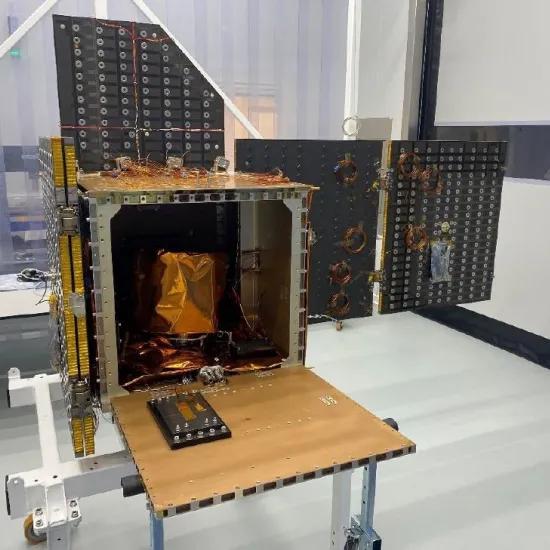

Within a European project, Sirris is responsible for the production (through additive manufacturing) and testing of samples. In this context we have been developing copper and copper alloys on our electron beam melting machine.

Additive manufacturing processes are able to produce parts with complex shapes and, therefore, allow the design of new products with enhanced properties (light weight, reduction of the assembly operations, optimum materials distribution according to the necessary parts properties, new design abilities). However, the quality of the final product, and even of the final material, is strongly dependent on the process conditions and on the composition of the basic raw material. The materials in use are still very restricted today, due to the process-related constraints in combination with specific materials properties which aggravate their processing to valuable parts.

Therefore, a consortium, consisting of Sirris and the German research institutes FEM and Fraunhofer UMSICHT institute, set up a European Cornet project, PONAMP - Products optimisation with New Additive Manufacturing Powders (PONAMP), in which the focus is on powder-bed-based additive manufacturing of metallic parts, i.e. on parts manufactured by the LBM and EBM processes. Two materials classes will be in the focus of the project: copper and copper-base alloys and aluminium alloys.

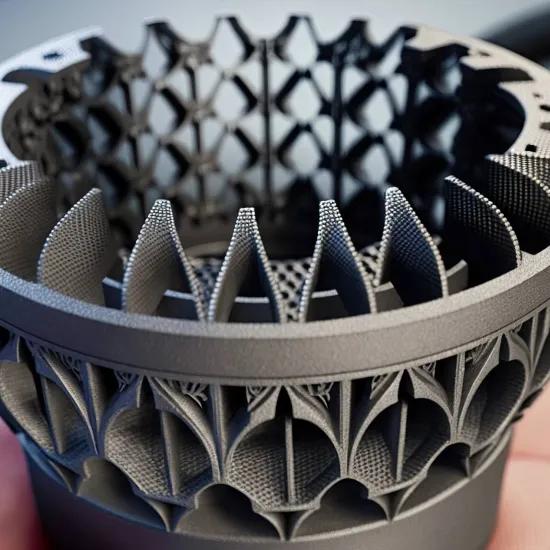

Copper cubes

As part of Sirris’s work within the project, the development of copper and copper alloys on our EBM machine requires first mastering the material development step on our electron beam additive manufacturing machine (ARCAM A2). The first cubes above are the onset of numerous future cubes aiming to identify the optimal set of building parameters.

EBM allows to print ultra-pure copper and avoid absorption issues, which are common with laser systems, and to reach densities above 99,8%. Sirris aims at using powder +45-90 µm to explore the possibility of improved surface state thanks to finer powder.

Further updates to come in the future!

PONAMP is a Cornet Project funded by national agencies members of the Cornet Network: German Federation of Industrial Research Associations (AiF) | Federal Ministry for Economic Affairs and Energy | Service Public de Wallonie - DGO6 (SPW).