The best market-ready solution to decarbonize heat in your industrial production

This article is co-authored with Giuseppe Casubolo - Director at Vola Alto Consulting

A viable solution for industrial decarbonization today

Implementation of renewable energy and electrification of transport and industrial processes heat are key pillars of many nations' strategies to reduce carbon emissions—and rightly so. We urgently need to cut emissions, and 90% of those reductions can be attained through energy efficiency and electrification based on renewable energy.

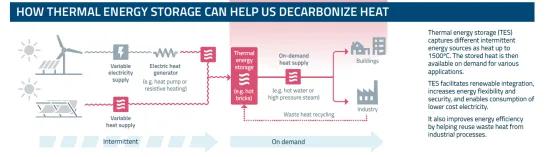

However, the main challenge with renewable energy is its intermittence as the availability of natural resources fluctuates. Thermal energy storage (TES) reduces peak energy demand and lowers production costs while reducing CO2 emissions by storing (renewable) energy during low-demand periods and utilizing it during high-demand times. TES also enhances energy efficiency and supports peak shaving by leveraging off-peak power and waste heat, offering balanced energy loads. And it does it all, even when the wind is not blowing, or the sun is not delivering solar energy.

High potential

TES can facilitate the introduction of higher shares of renewables and contribute to decarbonizing key sectors such as power, industrial processes, district heating or cooling, cold-chain applications and buildings. In 2020, around 234 GWh of TES was installed globally, and according to IRENA, TES capacity is expected to experience a threefold growth by 2030, reaching 800 GWh.

High Technology Readiness Level (TRL)

Although electrochemical storage technology is advancing rapidly (Li-ion batteries, etc.), alternative energy storage solutions such as thermal energy storage technologies, offer many different advantages among which, lower degradation (much higher lifespan), safer use with no fire risk, high TRL (on average 7 to 9) and less dependency on the supply of critical raw materials, often found in geopolitically challenged nations and extracted with lower environmental sustainability.

What types of Thermal Energy Storage are there?

TES technologies are categorized into three main types:

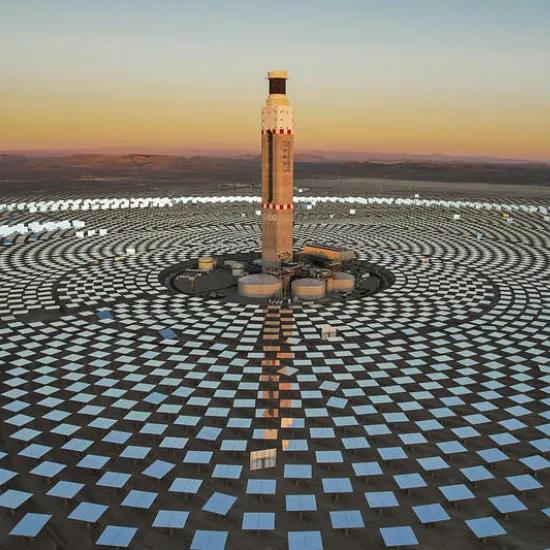

Sensible Heat Storage (SHS) - Thermal energy is stored by increasing the temperature of a solid or liquid medium, such as water, rocks, sand, or molten salts. This technology has the longest proven track record, as it has been widely used in applications like solar thermal power plants (CSP).

Latent Heat Storage (LHS) - Phase change materials (PCMs) store energy at a nearly constant temperature. Although this concept is simple, systems based on this technology require specially designed materials and are still under development.

Thermochemical Storage (TCS) - reversible chemical reactions are used to store and release thermal energy. This method offers high energy densities, high efficiencies and long-term storage potential, making it attractive for seasonal energy storage. However, more R&D activities are needed to reach a commercial level.

The role of heat generation in climate change

Energy use for heat generation is responsible for over 25% of global greenhouse gas emissions (the industry accounts for 14 Gt CO₂/year out of 55 Gt total emissions, buildings for 5,5 Gt/year).

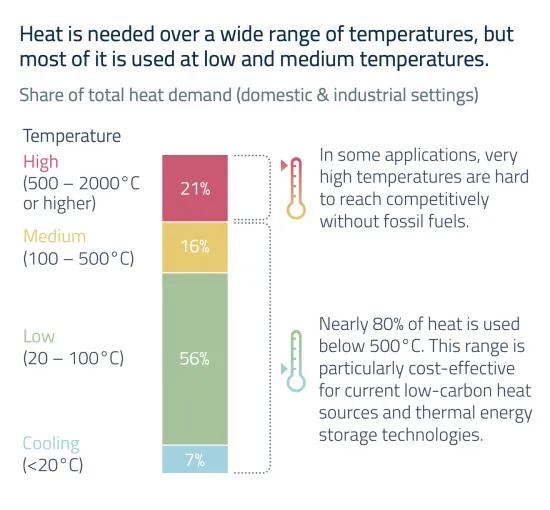

Heat accounts for 50% of global final energy use, yet only 25% is derived from renewable sources (mainly biomass usage), with the majority (75%) still relying on non-renewable sources. Heat demand spans a range of temperatures.

The importance of TES for decarbonizing heat

Coupling TES with an electrical boiler in industrial heat production processes makes it possible to achieve a complete "fuel switch" from fossil-origin to an entirely renewable one. In this way, it is possible to completely decarbonize steam into green steam with today's technologies.

How to fund your thermal storage installation?

CAPEX: You invest in your own thermal energy storage installation

OPEX: Heat Purchase Agreements (HPAs)

To advance the adoption of TES, some technology providers (f.e. Brenmiller, John Cockerill, Kytogroup, Energynest, etc.) offer Heat Purchase Agreements (HPAs) to their customers, similar to leasing contracts. They provide financial predictability for energy producers and enable companies to meet sustainability targets without significant upfront costs with the benefit to move from a CAPEX to an OPEX case. Companies can purchase renewable thermal energy at stable prices by entering into long-term contracts with thermal energy producers without investing directly in building their own thermal energy storage infrastructure. Similar to Power Purchase Agreements (PPAs), Heat Purchase Agreements (HPAs) offer companies a reliable and cost-effective way to secure green thermal energy (steam, thermal oils, hot gasses) while drastically reducing their emissions balance. HPAs are particularly valuable in industries transitioning from fossil fuels to electrified processes, to achieve their sustainability targets. HPAs also play a critical role in driving the energy transition by supporting the expansion of renewable energy projects.

OPEX: Heat as a Service (HaaS) or Heat as a Product (HaaP)?

TES technology providers can offer HPAs through "Heat as a Service" models. This is an ‘all-in’ contract for heating. The co-owner no longer buys a collective heating installation, but only the heat it consumes. The provider takes care of everything: the design, installation, maintenance, repair, as well as the financing of the works and gas supply. All technical, financial and administrative aspects are included in the contract. One less worry for co-owners, because in case of breakdown or technical failure, they do not have to pay one euro more.

McKinsey points out in their whitepaper "Tackling heat electrification to decarbonize industry":

"Our research shows that heat as a service within industry processes is less popular than on-site generation with combined heat and power (CHP) technologies. However, because of the additional capital needed and the technical novelties that come with electrification technologies, industrial customers with high reliability requirements might favor heat-as-a-service models."

Ready to feel the Thermal Storage heat?Join us on February 20th in Antwerp. |