The Bio-Manufacturing project, coordinated by Sirris, has been elected by the Walloon Region to participate in the RegioStars Awards, that rewards the best European regional projects.

The Walloon Region selected the project for its development of a Bio-manufacturing Platform for the development of innovative brain-controlled mechanical prostheses and orthoses. The case of a leg orthosis controlled by a helmet analysing brain waves was chosen and developed in this project thanks to additive manufacturing technologies and know-how in the management of biological signals in a non-invasive way. This first step generated a lot of other biomedical projects and developments as well as the creation of new companies.

Use of accessible biological signals

Despite the significant development of technologies in the field of industrial robotics and the emergence of robots for household tasks, little progress has actually been made in the field of prostheses and ortheses, which are offered daily to patients suffering from paralysis or having undergone amputation of limbs.

However, the development of knowledge in the fields of neurophysiology, microelectronics and computer technologies should make it possible to better use accessible biological signals in a non-invasive way such as electro-encephalogram (EEG) and electro-myogram (EMG) and use them to compensate for disabled subjects' deficient motor controls. Researchers around the world agree that this new century will be the one that will integrate human brain capacities into machines.

Contents of Bio-Manufacturing

In the project, Bio-Manufacturing, which ran from 2008 to 2013, the basic idea was to use an artificial neuronal network to allow patients to order the prosthesis or orthesis in a natural way while maintaining its natural procedures.

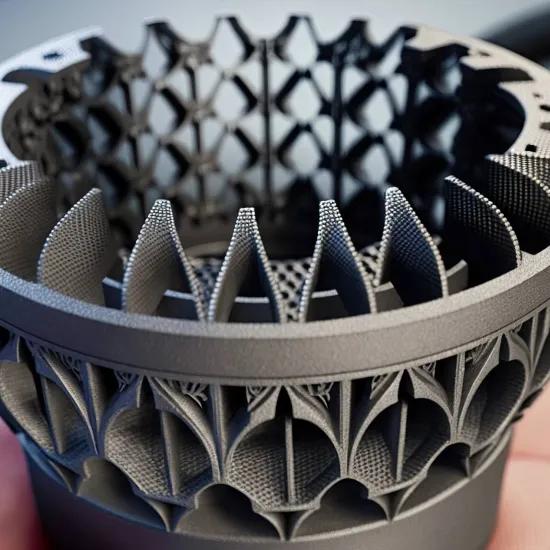

The second idea was to design and produce these complex medical devices with additive manufacturing (AM) technologies to go one step further than conventional ways of manufacturing. In 2008, this choice was considered risky, since the number of biomedical applications of 3D printing was rather low.

The combination of these two innovations resulted in interesting case studies of smart ortheses driven by neuronal control system (foot lifter, helmet with sensors).

The Bio-Manufacturing platform is based on several complementary actions, new high performance equipment and specific competencies of research centers, universities and companies in the Walloon region.

Finally, this project opened the door for the development of smart prosthesis with integrated control system, but the competence developed in this project has made it possible to work lateron on other biomedical applications such as surgery tools and intervertebral cages.

The Bio-Manufacturing project was important for Sirris to launch industrial activities and introduce 3D Printing in the biomedical field. For example Sirris set up a new additive manufacturing process to produce implants with a fully bio-compatible material which was not available for 3D printers. This development allowed the production of thousands of intervertebral cages with the French company Kasios, which is now installed in the Walloon region. The exploitation of Sirris results for other similar applications led to the creation of the CERHUM company by a Sirris engineer to focus on 3D Printing of ceramic parts.

The Bio-Manufacturing project has been elected by the Walloon Region to participate in the RegioStars Awards, that rewards the best European regional projects, for category 5 - Modernising health services.