The intention to start using AM too often bumps into a lack of expertise and know-how. Here is where projects such as INSIDE metal AM come to your aid. It’s not just about selecting applications suited for AM, in a next step the right technologies for the job have to be identified and implemented. Here is your chance to learn all about this recently closed project.

You think 3D printing with steels could be an innovative and efficient technology for your company? Considering an investment in additive manufacturing equipment or start exploring in collaboration with a printing service provider?

Often these questions are the start of a journey towards the potential use of additive manufacturing (AM). The intention to start using AM can come to you after having seen applications that were developed in other industries or because you are convinced your company should adopt this new and exciting technology. But once you start digging deeper you realize there is a lot more to it. In a recent survey performed by Flam3D, companies from different industries and sizes have stated that the “lack of internal expertise and know-how regarding AM” is an important obstacle for them to go ahead.

Good news

Thanks to funded Flemish initiatives such as the recently closed INSIDE metal AM project you don’t have to have to build up all the required know-how on your own. The experience gathered within these projects and the support given by experts from organizations such as the Belgian Welding Institute, CRM Group and Sirris can also help your company to successfully select the application suited for AM and in a next step identify and implement the right technologies for the job.

As mentioned before, preparing the purchase of a 3D printer or selecting a service provider that fits your needs, is merely the start. If you want to accomplish a successful 3D-printed product, there are various activities, apart from the actual printing, that have to be taken into account.

The INSIDE metal AM project does not answer all business and technology related questions you might have on this rapidly evolving subject. It does however cover many key aspects and activities relevant for current and future users of metal AM. The information and gathered experience has been compiled in reports and other documents for communication purposes.

These include, among others:

- information on raw materials and their quality control

- processability info obtained while manufacturing simple geometries

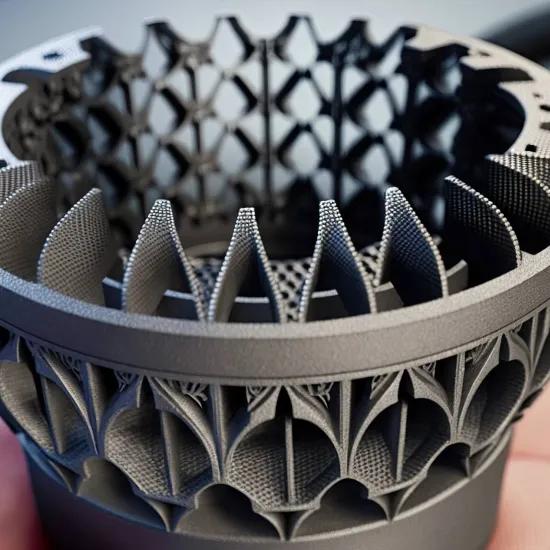

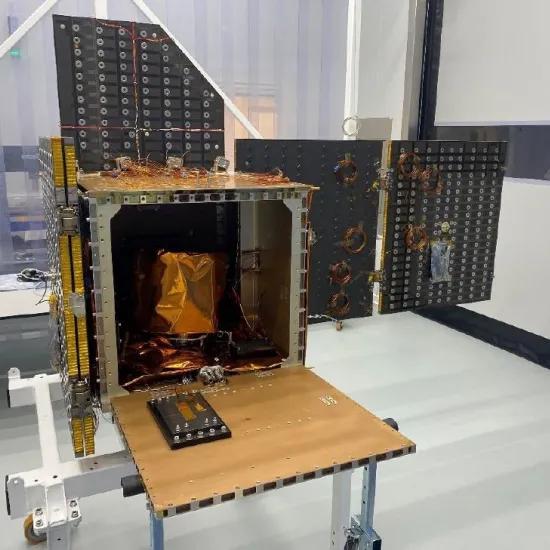

- industrial demonstrators produced by different relevant AM technologies (L-PBF, LMD and WAAM)

- information on obtainable material characteristics for several relevant steels (316L, 17-4PH, H11, 2209 duplex steel), demonstrating their performance

- a study on the impact of heat treatment

- an overview of surface postprocessing efficiency (tribo-finishing, electrolytic polishing etc.)

Want to know more?

Questions you want to ask us directly? Contact us, we will be happy to help you out of discuss your ideas!

This project has been realised with the support of Vlaio and the Strategic Initiative Materials (SIM).