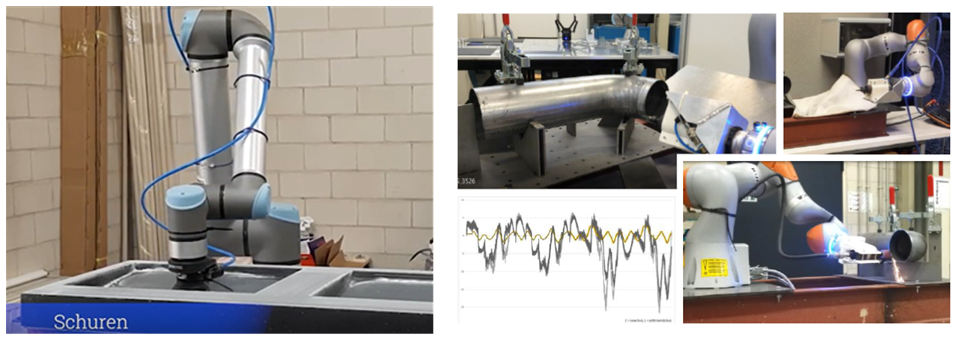

COBOFIN | Robotic sanding and deburring

The COBOFIN project aims to accelerate the introduction of collaborative robots - as assistants next to experienced operators - for automated sanding and deburring of small series. It will help companies to make these processes more qualitative, competitive and enjoyable.

Context

Plastic and metal parts often need finishing (deburring, sanding,...) in order to achieve the required final quality. Today, these post-processing operations are mainly manual. The finishing operations are regarded as monotonous, stressful, dirty, time-consuming and costly. In addition, many companies do not find suitable personnel to carry out these tasks. Automation of these operations is therefore necessary in order to remain competitive!

Commercial automation solutions are available for finishing large series of identical products. However, automating the finishing of small series of different products (high-mix, low-volume) is less obvious. Fortunately, technological progress in the field of collaborative robotics (cobots) enables a practical approach to automate the post-processing of small series. Instead of trying to eliminate operators through automation, a user-friendly assistant (cobot) could support the experienced operator by taking over certain repetitive, dirty, stressful tasks. The cobot thus increases the finishing capacity of the operator.

Purpose

The COBOFIN project aims to accelerate the introduction of collaborative robots- as an assistant next to an experienced operator- for automated sanding and deburring of small series.

The project aims to achieve concrete, practically usable results such as overview publications, pilot setups, decision tools, hands-on workshops, training programmes, a step-by-step plan and guidelines, so that the companies can get to work with the project results themselves.

Approach

In this collective research project, we want to accelerate the introduction of cobots for the post-processing of parts by focusing on the following partial aspects:

- Technological feasibility of cobots and power-controlled feedback for deburring and sanding parts: what can be automated and what not? What quality can be achieved for increasing complexity? Which cobots are suitable and what are their advantages and disadvantages? Which tools can be used by the cobot? Which sensors can be used? Etc.

- Economic feasibility of cobots and power-controlled feedback for deburring and sanding parts: which criteria and parameters play a role in determining the ROI? What are the benefits and how can they be quantified? What are the typical costs and how can they be quantified, etc.?

- Low-threshold programming of cobots for flexible use: which concepts or solutions for programming are available and what are the advantages and disadvantages? What level of ease of use is achievable? Etc.

- Integration of cobotised finishing in an SME production environment: what is an optimal design for the cell with regard to supply and discharge, manipulation of the parts, ... How can the range of the cobot be increased? To what extent should the workplace be adapted (e.g. extraction)? How to manage the tools? Etc.

Target group

The project focuses on aspects relevant for companies with manual sanding or deburring processes on small series and single pieces.

The industrial user group of the COOCK project provides input for the specification of typical applications and produces representative use cases. The members of the user group will have priority when it comes to knowledge acquisition and are invited to experiment with relevant cases.

Manufacturing companies and technology suppliers (e.g. automation companies, integrators, suppliers of emerging technology, ...) which have registered, are also part of the industrial user group.

Funding

COBOFIN is a COOCK project, supported by VLAIO.

Reference

COBOFIN: HBC.2020.2534