In the first part of this series we discussed the productivity of Belgian companies. Productivity growth in our country has been substandard in recent years and, compared to our neighbouring countries, we are lagging behind. Productivity growth is a measure for long-term prosperity. The Study Committee on Ageing calculated that the affordability of pensions depends for 8/9ths on productivity growth and for 1/9th on employment grow.

In order to support Belgian companies to improve their productivity, we are putting together a number of tips that will be published at regular intervals. These tips address improvements that can be achieved easily by everyone.

Tip 87: Shortening downtimes in the event of failure

Two factors are decisive for a machine’s productivity: the mean time between failure (MTBF) and the mean time to repair (MTTR). The time between failures can be increased by stepping up preventive maintenance (see tip 26). A number of simple interventions also make it possible to reduce the downtime:

- Make sure that faults are noticed quickly, for example, by using (flashing) signal lights or by sound alarms. If you use a different tone for each workstation, staff can quickly identify the source of the malfunction.

- Provide clear information on the nature of the failures in a language understood by the operators. 'FEHLFUNKTION 342' doesn’t mean anything. 'Paper jam Tray 2 - Open tray and remove paper' is more understandable.

- Make clear agreements on what to do in the event of a failure. Determine who is authorised to repair which failures, in order to prevent further disruption of machines. Also determine how long the operators can try to solve the problem themselves before they have to call in help. Also stipulate who they should contact and how (don't mail, call!).

- Make it easy to call in help. For example, in one company the helpdesk number was affixed to every phone with a sticker. This does not only ensure that no time is lost in looking up the number, but also invites you to call for help on time.

- Provide proper training and instructions on how to fix the most common malfunctions. The Pareto rule often applies in the event of a malfunction (see tip 82). It states that 20% of the causes of failures account for approximately 80% of the failures. Therefore, focus the training and instructions on the most common faults.

The video below illustrates how one company was able to reduce downtime by improving instructions to operators through the use of QR codes and video instructions (see tip 54).

Tip 88: Do NOT sell too much

In many companies, there is no adequate cooperation between sales and production and the two departments are at odds with each other. Salespeople receive incentives to maximise sales, while production is told to minimise costs. However, everyone’s aspiration is to increase profits. This strategy is demonstrably wrong. By giving incentives to salespeople, salespeople tend to offer discounts, which means that while sales are rising, overall profits are shrinking. This is particularly painful when the organisation is already straining against its capacity limits, because it invariably leads to additional costs (overtime, temporary work, additional outsourcing, etc.), weakening of delivery performance, which in turn results in damage to the company’s reputation and dissatisfaction on all sides. In other words, selling more units than the available capacity is counterproductive.

The solution, however, is simple: stop unintentionally overloading the ship until it sinks. The task of sales is not to increase turnover, but to maximise profits taking into account capacity constraints.

To structurally improve the cooperation between sales and production, it helps to organise a 'Sales and Operations Planning (S&OP)' meeting. This means that representatives from sales, production and procurement meet on a monthly basis to discuss medium and long-term planning. By getting together on a regular basis, production can align its capacity with the expected market developments and sales will know exactly how many items per product family can be sold. By focusing on the most lucrative customers and products, sales can maximise profits without causing unnecessary problems through excessive sales growth. (See also tip 71 about good pricing)

It is also important to optimise the sales incentives scheme. Do not provide a commission on turnover, but rather a commission on realised margin of the delivered products.

Tip 89: Visit other plants

Visiting other companies is an excellent way to find inspiration to improve your own business. By visiting other businesses, you not only learn what has worked for them, but also gain the confidence to try it yourself. Seeing is believing.

During a company visit, there is often a lot to see, and it is easy to become overwhelmed. Try to focus on a limited number of points that you want to learn from and ask targeted questions. A guided tour is an ideal opportunity to train your observation skills. For example, during a tour you can estimate productivity by means of a multi-moment record (see tip 16), make an estimate of the amount of stock (how old is the stock?) or have a look at the information boards (are they up to date?).

Every year, after a rigorous selection process, some manufacturers in Belgium are crowned 'Factory of the Future'. These are the absolute top companies with an excellent track record in several areas and can be visited via Agoria's annual roadshow. More information is available here.

Tip 90: Avoid over-engineering

"There is nothing so useless as doing efficiently that which should not be done at all," preached management guru Peter Drucker. This may seem obvious, but many companies fall into the trap. Over-engineering is a good example.

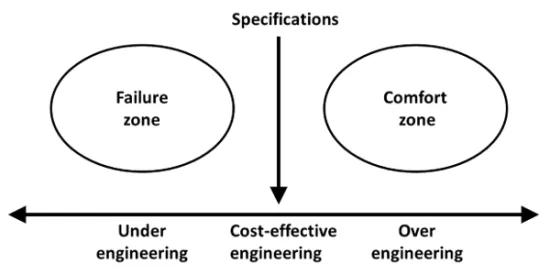

Over-engineering occurs when solutions are designed that are more advanced than necessary. Over-engineering is common in hardware development and particularly problematic in software. Over-engineering typically involves adding functionality that is not needed, eliminating drawbacks that are acceptable to users, or exceeding design specifications. Rolls Royce, for example, once designed a remote control to operate the car radio from the back seat. However, customers did not care about this, they just asked their driver to operate the radio.

Over-engineering reduces the productivity of designers, increases production costs for hardware and maintenance costs for software, and prolongs time to market. Ultimately, a new product introduction may even flop because the product is considered to be too expensive, or too complex.

Over-engineering can be avoided by focusing on the following elements:

- Do not try to design a product that can do everything for everyone, but design your product with a specific market segment in mind.

- Understand what your customers really needs and what they are willing to pay for. Some needs are only 'order qualifiers', for which meeting the minimum is enough. For example, for many customers, a full-sized spare wheel in a car is not necessary, and a cheap tyre repair kit is sufficient.

- Brainstorm about the simplest solution to a problem. The most sophisticated solution is not the best solution! (see also tip 43).

- Be cautious about designing features that may only be relevant in the 'distant' future or in exceptional cases.

- Provide complete and clear specifications and record the corresponding test methods.

- Test the design for under-engineering (premature failure) and over-engineering (e.g. unnecessarily solid).

- Also take into account over-engineering in the related aspects (packaging method, maintenance frequency ...).

- Discuss the characteristics of over-engineering (e.g. weight, cost, size) with the designers and challenge them to come up with a solution that is e.g. 10% better.

- Design with the widest possible tolerances and avoid using exotic materials.

Finally

Do you have any tips to share? Let us know so we can share them and become more productive together. The best tipster of the week will get a nice gift!

You can find an overview of the other parts of this series with tips here.

Shortening lead times makes it possible to grow as a company and to reduce lots of indirect costs. The quick response manufacturing (QRM) production strategy makes this possible for companies in a high-mix, low-volume environment. From 8 November (Ghent) and 17 November (Diepenbeek) we organise a next QRM training cycle.