Belgium is the fourth most productive country in the world, but our productivity growth has been sputtering. In this series we present practical tips each time to boost productivity in the office and on the shop floor.

In the first part of this series we discussed the productivity of Belgian companies. Productivity growth in our country has almost come to a standstill in recent years. Belgium is not the only country struggling with poor productivity growth. Productivity growth in Germany is also at its lowest level since World War II. Ten years ago, hopes in Germany were pinned on Industry 4.0 to turn the tide. Unfortunately, German productivity figures do not yet show any sign of a fourth industrial revolution, which has led to criticism.

In order to support Belgian companies with their productivity improvements, we collect a number of tips that we will publish at regular intervals. During our company visits, we see that there is still a lot of low-hanging fruit to be picked. These tips are therefore not only aimed at implementing advanced technologies, but also at improvements that can be easily achieved.

Tip 79: Produce the right numbers

(Source picture: https://unsplash.com)

Producing goods that nobody needs is the biggest possible waste. Yet we see companies everywhere producing more than what their customers order because they believe producing large quantities is more efficient. However, this is a dangerous thought. We recently saw a company that had produced a large lot of 1,500 units, saving a lot of changeovers. When it turned out that the annual demand for the item in question was only 2 pieces, and they became aware that a stock for 750 years had been built up, it became clear that almost all the work had been completely pointless.

Of course, there are cases where it does make sense to produce more than what the customer needs at one specific time, but this should be handled with the utmost caution. It is not uncommon for the forecast to be wrong or for the customer's wishes to change, which ultimately leaves you with unsalable stock. A good way to assess this risk is to check how much stock has remained in your warehouse for more than one year.

Producing more than you strictly need has many negative effects. Overproduction creates additional inventory. The costs associated with holding stock are generally underestimated. The annual cost of holding inventory is typically 15-25 percent of the inventory value. Just think of the capital costs, the warehouse costs, the administrative costs (e.g. stock counting), insurance costs, and of course also the costs related to lost, damaged and unsellable stock.

By spending time overproducing an order, you are also making the other customers wait. This leads to unhappy customers, and possibly overtime to get other orders out on time.

Do you want to produce more than the immediate demand, because you suffer from long changeover times? Then read tip 34 about reducing changeover time.

Tip 80: A simple method for managing your residual stock

(Source picture: https://unsplash.com/photos/S32zqWHnYwk)

The processing of pipes, profiles or plates often leads to a residual stock. Residual stock is often not adequately managed, resulting in extra manual counts, stock-outs and unproductive emergency actions. The problem starts in fact when you do not make a proper distinction between the actual residual stock and the stock of complete materials. For example: suppose you still have 30 meters of piping in stock. Does this mean 5 usable pipes of 6 meters, or 30 unusable bits and pieces of 1 metre?

A simple method to clarify this is as follows:

- Create two stock locations in your ERP system: one for the complete materials and one for the residual stock. Do a stock count and register all complete materials at the stock location for complete materials and the residual stock at the location for the residual materials in your system.

- Set up the system to ensure that material is always consumed from the residual stock location (e.g. via the backflushing functionality).

- Then give your employees two instructions:

-

- Always use up the residual stock first (this limits the remaining stock)

- If you use complete materials, you must first transfer it in the system from the complete material location to the residual stock location.

This approach allows the planner to see at all times how much complete material is available by consulting the stock data in the complete material location. The distinction between the two location types is one that must be made in the ERP system, but not necessarily on the shop floor. The complete and residual stock materials can be stored together on the shelves, the distinction must only be made in the ERP system.

The only thing that changes in the operators’ daily practice is the extra registration when they take something from the complete stock. This registration can be done by means of a barcode scanner, or directly in the ERP system (see tip 11 about using ERP on the shop floor). Check whether this is done correctly in the beginning by making some cyclical stock counts of the full material (see tip 21 about cycle counting).

It is also recommended to make clear agreements about the management of very small, unusable residues. Agree with your employees on a minimum residual size. Anything smaller should be thrown into the scrap container. This way you prevent unusable residues from taking up space and you still earn some money from the scrap. You could, in theory, ask employees to book these very small scraps into the system to keep the residual stock correct. In practice, this is often too much to ask, and it is not even necessary for stock management. After all, stock management is only done via the location of the full materials. It is therefore sufficient to carry out an annual count of the residual stock.

Tip 81 : Do not give a discount if there is pressure on prices, but offer something extra

(Source picture: https://www.pexels.com)

Implementing a smart pricing policy is an important lever to boost revenue, and therefore productivity (see also tip 71 on pricing). If price pressure is high, sellers are often tempted to offer a discount. A better alternative is to offer something extra to the customer.

An example: suppose the customer wants ten items of a product and insists on a nice discount. In this case, it is better to offer him a free eleventh product. For example, the customer gets eleven products for the price of ten, or the equivalent of a 9.1 percent discount per product. Now if the price of a product is € 100 and the variable cost is € 70, then the contribution of the eleven products is: 10 x € 100 (turnover) - 11 x € 70 (variable cost) = € 230. If you had offered an effective discount of 9.1 percent, the contribution rate: 10 x € 90.9 (turnover) - 10 x € 70 (variable cost) = € 209. So offering an extra product brings in more money than giving a discount.

This difference exists because you offer the customer € 100 extra value, while it costs you only € 70. Other alternatives for increasing the quantity are, for example, offering an upgrade, extra accessories, spare parts... for free

An added benefit of this approach is that you can keep pricing intact, and customers won't get used to lower prices.

Tip 82: Do NOT strive for perfection, use the 80/20 rule

"Always aim for perfection" is a well-known management principle. Frequently used terms such as 'zero defects', 'zero inventories', 'first time right' are illustrations of this pursuit of perfection. At first glance, this seems a noble ambition, but appearances can sometimes be deceptive.

Joseph Juran, the father of quality management, noted that typically 80 percent of problems are caused by about 20 percent of the problem causes, and called this the Pareto rule. The Pareto rule implies that 80 percent of possible progress can be achieved by eliminating 20 percent of the problem causes. Or even, to achieve the final 20 percent improvement, 80 percent of the problem causes must be fixed. So the last 20 percent improvement requires four times as much effort.

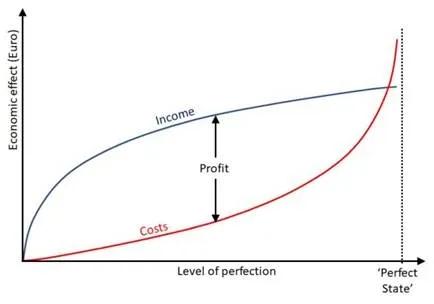

The chart below visualizes this insight from Juran by showing the revenue and cost of improving. As the products and services get better, hopefully the customer will want to buy more or pay a higher price. In addition, some costs will also decrease. For example, the cost of ‘rework’ will disappear. Therefore, as one improves, the yield increases. This increase gradually levels off, as each additional improvement yields less and less (blue line). Economists call this the law of diminishing marginal utility. As perfection is achieved, we also see the costs increase (red line) because, according to the Pareto rule, each additional percent of improvement requires more and more effort.

The final profit is the difference between the proceeds and the costs. The diagram shows that the profit reaches the maximum when you’re not in the perfect state. Perfection, then, is far from ideal; more to the point, perfection is the enemy of what is good. The productivity hall of fame is not reached by striving for perfection, but by carefully weighing the benefits against the costs. After all, the goal of productivity growth is not to keep improving endlessly, but rather to have to work less.

Therefore, make Pareto analyses of your problems to find out what you need to tackle first. Also define when a process is good enough. You don't have to score 100 percent for everything, sometimes 95 percent is simply better than 100 percent. A practical example of this is delivery reliability in a make-to-stock environment. In order to achieve a delivery reliability of 100 percent, one has to maintain an immense safety stock in order to be able to absorb all possible demand fluctuations. It is therefore often better to aim for a lower delivery reliability (e.g. 95 percent) that better optimises the cost of the safety stock against the lost revenue due to stock outages.

Finally

Do you have any tips to share? Send them to us, so we can share them and become more productive together. The best tipster gets a nice gift! We would like to thank Kurt Van Loock for providing the inspiration for tip 79.

You can find an overview of the other parts of this series with tips here.