Fact check: is low price the only reason to choose 'remanufactured' products?

Sometimes we hear that the low price is the only reason a customer would want to buy remanufactured products. That triggered us. We did some research and learned that there are more reasons to choose remanufactured products.

These reasons vary greatly. The main ones are:

1. The price/quality relation

Many customers are looking for alternatives to using a high-quality product at a low cost. The total cost of ownership (TCO) may be the driver for this. There is competition from PaaS models, take-back, extra services, upgradeability, etc.

Atlas Copco's subsidiary Originair sells remanufactured compressors. Customers naturally like the lower price, but always in combination with another reason: sometimes because the company standardises on brand for the sake of maintenance, uniformity, etc., but they still want to keep the costs down for some usage profiles (e.g. stand-by compressors). Other customers are mainly looking for a fast, high-quality solution.

2. Delivery time and/or availability

If the parts are to be used for repairs whose consequential cost (the cost of the time that the product, e.g. a production machine, cannot be used) is much greater than the absolute cost of the parts, the price may be less consequential: delivery time and availability of the part are then the value drivers that determine the price. If the new parts are no longer available because the product is out of production, the user has little choice. In such a case, users sometimes do not want to - or cannot - replace the machine (custom-made, large investment to replace with a completely new installation, etc.) and may be more prepared to pay for remanufactured parts.

Van Loock Motoren repairs and upgrades non-standard electric motors, including those installed as belt drives in a large installation. Replacing the motor with a new one would have major consequential costs, such as a different motor support plate, new belt pulleys, a new method for tensioning the belt or a different geometric arrangement that might require other parts of the installation to be adjusted. In this situation it can therefore be very useful to upgrade, repair and improve the controls on machines that are no longer on the market. The knowledge input and the associated repair and upgrade services therefore minimise the consequential costs.

3. Absolute value cash-out

For capital-poor companies that want to invest in a machine, the absolute cash-out may be the top priority. The cheapest solution at that time will be chosen. For products that have a short remaining lifespan but still need to be repaired, the lowest cost is naturally also decisive.

4. Maintaining a relationship (quality, service, etc.) with the supplier

Customers who choose your product and service, standardise on your brand or opt for an A-brand sometimes have products that are not used so intensively or that only need to be used for a specific project. In these situations, there is no guarantee they will use these products for a long time. The choice for quality but at a low cost is then very rational.

Even if services are aimed at product upgrades, repairs, etc., the customer can opt for remanufactured parts. The service contract can explicitly state that remanufactured parts may also be used in the service.

At the REM-B company, there was a planned production shutdown of a machine for which the standard hydraulic components had to be repaired and upgraded. A quote was made based on what needed to be replaced and the price-quality relation compared to that of using new hydraulic components. In this case, a combination of service factors including lead time and a detailed inspection report on parts convinced the buyers.

5. To also be able to return old parts

For products that contain hazardous substances, or for which specific waste processing regulations apply, the customer may be happy to exchange their 'old' parts for new ones. The price is then related to the waste processing costs. It also relieves the customer of all worries because one partner takes care of the 'exchange' and everything that comes with it (logistics, waste collection, etc.).

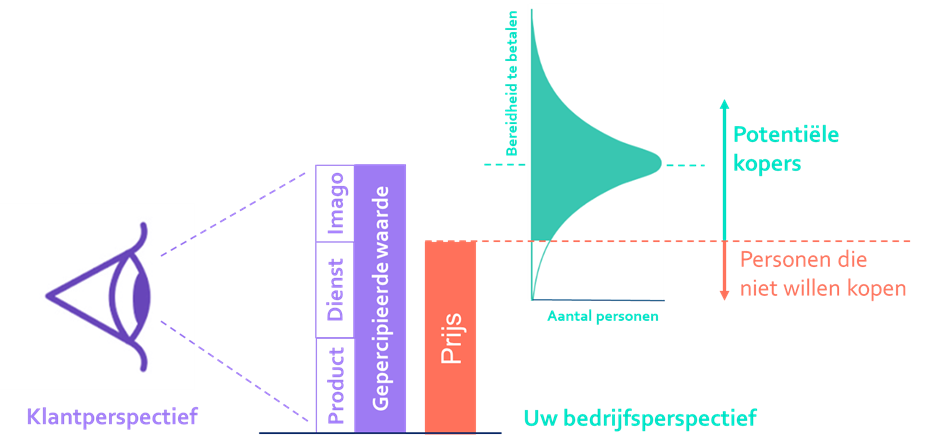

The product-service-image mix

There are other reasons why customers choose remanufactured products, but these stand out above the rest. As in any revenue model, the product or product-service combination offered must meet a customer's actual need. Customers (and companies) are people, and people are never completely rational. This means that some non-tangible reasons play a role, such as conviction and image.

The customer's willingness to pay therefore depends on the match between customer need and the customer's perceived value of your offer. It is the combination of products, services and image that determines the value for the customer.

|

Remanufacturing, repair, upgrading, refurbishing, reuse, ... these are all valuable circular strategies, but how can you be sure that you are exploring and testing the strategy best suited to an SME context? By way of the COOCK project 'CIRKEL - Remanufacturing as a lever for value creation in a circular manufacturing industry’, with the support of Flanders Innovation & Entrepreneurship (VLAIO), Sirris provides you with the strategy and practical tools (technologies, tools, etc.) that help you limit the risks and increase the opportunity for increasing success. Get started yourself with our useful tools

|

Would you like to know more? Then please feel free to contact us!