The specific heat of a materiel is an important property, equally in the field of industry and in research. It applies in the improvement of processes such as injection moulding, in risk analysis and in the construction of chemical reactors. Other sectors such as the pharmaceutical industry and the food industry are also concerned by this measurement.

Specific heat can be measured using DSC (Differential Scanning Calorimetry) in three different ways: the direct method, the sapphire method and the IsoStep DSC method. The first two solutions rely on a linear temperature programme, the third on a periodic temperature programme.

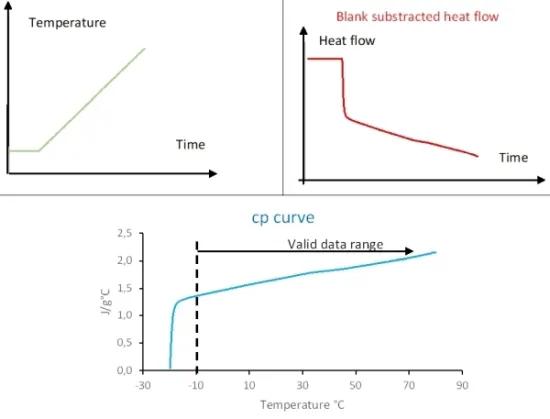

Direct method

Test conducted on polypropylene:

- The temperature programme comprises an isotherm and a heat phase.

- The heat flow is divided by the heating rate and the sample mass m to obtain the cp

- It is also possible to conduct the test without an isotherm; however, this reduces accuracy.

Sapphire method

Test conducted on polypropylene:

- The temperature programme comprises an isotherm, a heating phase and a second isotherm.

- Three measurements are required: blank, sapphire and sample.

- Comparison of the cp of a reference material subjected to the same temperature programme.

- Measurement can also be conducted without the isotherm segment, but as in the direct method, accuracy is reduced.

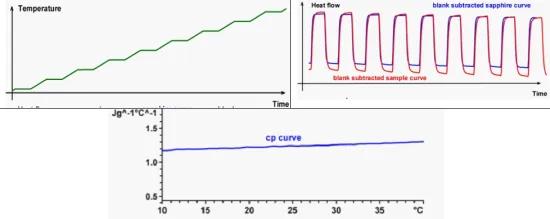

IsoStep DSC

- Test conducted on a Standard PS NIST.

- The periodic temperature programme comprises an isotherm and a heat phase.

- Short temperature interval.

- Each segment lasts at least one minute to ensure stable conditions.

Comparison

Source Mettler Toledo: Webinar : Specific heat capacity - Determination by DSC (2012)Further information on Mettler Toledo DSC 3+ can be found on our Sirris Test Labs website.

DSC is one of 4 tools in our new thermal analysis chain. It also includes a Flash DSC 2+, a TMA SDTA2+ and a DMA SDTA861.