Sheltered workshop Mirto classifies and sorts products and material flows

Mirto, with sites in Ghent and Eeklo and more than 300 employees, offers various customised solutions, including logistics, mailings, e-fulfilment, packaging, filling animal feed and washing product packaging, vegetation management, and annotating and labelling data.

Sheltered workshops like Mirto play an important role in the circular economy by identifying and sorting products and material flows. This article shows how this supports businesses with their circular projects.

How are products and material flows identified accurately?

The importance of understanding material flows

In a circular process, understanding the composition and variation of materials is vital, especially in the exploratory phase.

Sheltered workshop Mirto’s unique approach

Mirto helps businesses with:

- Identification: Determining what materials a flow contains.

- Classification: Categorising materials.

- Annotation: Adding information and labels.

This data is used to train AI models. The data forms the basis for automated processes such as sorting and recycling and provides crucial insights at an early stage.

Manual sorting of material flows

Automated sorting is rarely profitable or practical during the exploratory phase. Mirto therefore manually divides the material flows into different fractions. This helps businesses to gain insight quickly into the possibilities and challenges their flows present.

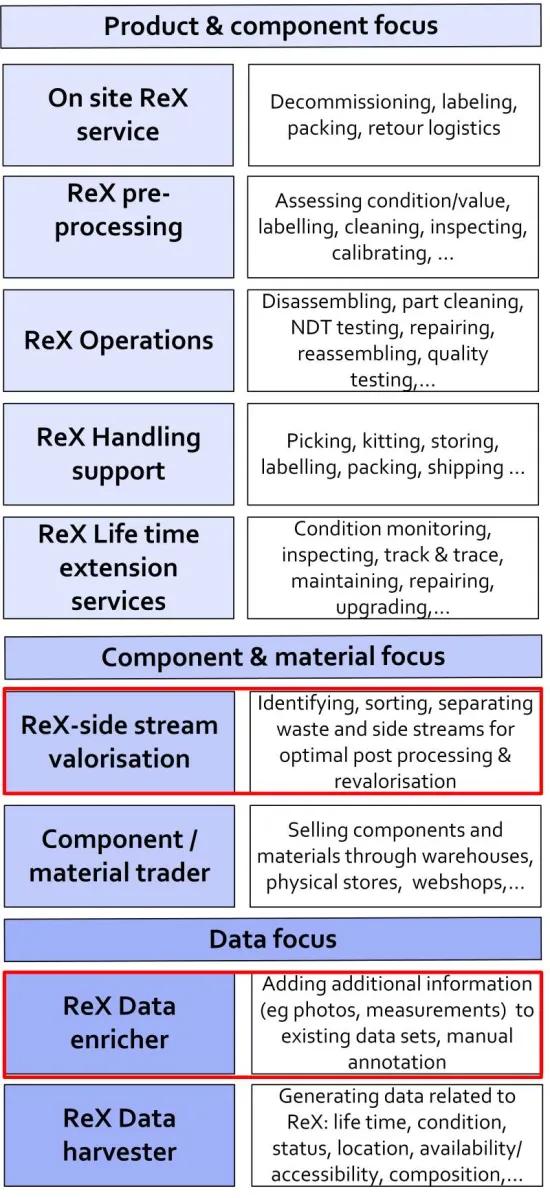

Overview of activities relating to ReX to which sheltered workshops can contribute

Successful circular projects with sheltered workshops

Mirto has built up valuable experience in recent years by working with leading partners in the circular economy.

- Recupel: categorising residual flows of electrical and electronic equipment

Mirto classified and photographed many tons of residual material in order to collect the data needed to train AI models. These models recognise different types of devices, such as smartphones, vacuum cleaners and computers. Mirto’s thoroughness gave Recupel a better understanding of the composition of discarded electronic devices. This improved its waste processing.

Planum project: eco-friendly dismantling of old aircraft

A consortium led by Sabena, with partners such as Comet, UCL and Sirris, looked at how old aircraft could be dismantled in an eco-friendly manner and the parts and materials reused.

Mirto manually sorted shredded aircraft seats into four fractions:

- metals

- foam and textiles

- hard plastics

- a residual fraction

The sheltered workshop took care of everything: sorting tables, packaging, weighing the fractions, taking photos and shipping. This fast and thorough sorting gave the consortium valuable insights into the reuse of aircraft materials. This project shows how collaboration and a customised approach go hand in hand with circular innovation

Key insights from working with Sirris

The collaboration in the Planum project yielded key insights that extend beyond sorting material fractions. In this way, pilot projects can be a stepping stone to scaling up and creating continuous employment – an important ambition for Mirto.

- Open collaboration and an entrepreneurial mindset:

Innovations in the circular economy are often new territory for everyone involved. A proactive and constructive mindset strengthens the co-creation process. Qualities such as open-mindedness, curiosity, engagement and care proved to be crucial. Asking carefully about the customer’s needs and sharing expertise make quick, safe, high-quality sorting possible. - Exploratory versus operational phase: The project made it clear that manual activities play different roles in the exploratory and operational phases. Manual sorting primarily adds value for high-quality material flows, where reuse, refurbishment or remanufacturing has greater value retention potential than pure recycling

- Role of testing systems: Inspection and testing systems also play a role, for example in training AI machine vision. This ultimately leads to more advanced automated processes. In Mirto’s HAAI department, trained employees label or annotate the collected data.

Sheltered workshops as a driving force in the circular economy

Mirto demonstrates that sheltered workshops play an essential role in the circular economy. By working flexibly and sorting and identifying material flows effectively, the business contributes to a sustainable future centred around reuse and value retention.

Keys to success for this project with sheltered workshop Mirto

Some key factors that contributed to this project’s success were:

- Personal connections: The collaboration came about through personal recommendations. Sharing ideas, even without a concrete test case or project, proved to be a valuable foundation. Networking and knowledge-sharing are crucial.

- Enthusiasm from the start: Mirto’s enthusiasm and solution-focused attitude encouraged co-creation and stimulated the development of new ideas.

- Close collaboration: The work supervisor, the workshop personnel and customers formed a well-organised and efficient work organisation.

- Combination of manual work and data technology: Mirto combines its Circular Team’s practical skills with expertise in technology from its data-sensitive departments (HAAI, e-fulfilment and direct mailing). These excel at seeking out and integrating technology, both for carrying out the circular task and for processing and structuring data

Would you like to know more about circular projects?

For more information about Mirto's circular projects or the data annotation (HAAI) department, contact Luc Bulckaert (lucb@mirto.be -+32 494 872105).

Do you want to gain inspiration or learn more about how sheltered workshops tackle complex issues relating to extending product lives?