Polyurethanes can be used in many applications, due to their excellent combination of properties. Protective PU top-coats should withstand weathering degradation and prolong projection of steel substrates. Supporting the transition towards more sustainable PU coatings, a comparative testing on the performance of major bio-based alternatives for PU precursors was recently presented. From this research the potential of bio-based PU coatings proves to be significant.

Polyurethanes (PUs) are versatile polymers of interest for a wide range of applications such as foams, adhesives, coatings, paints, sealants, or elastomers. The PU can be synthesized with excellent chemical, physical and mechanical properties for tailored use, depending on the selection of isocyanates and polyols. Protective PU coatings are particularly known for their high level of durability, UV resistance, chemical resistance and hydrolytic stability. As the weathering degradation of PU top-coats was assessed more critically, the build-up of hydrophilic moieties during coating degradation promoted the absorption of water, thus leading to the formation of blisters on the coating surfaces after alternating dry and wet environments.

Weathering

The failure mechanisms of a polymer coating during weathering are controlled by a complex set of photochemical oxidation processes and the creation of reactive sites (e.g. scission of polymer chains, rearrangement and crosslinking, promoting final cracking). These reactions can be controlled through the optimization of clearcoat composition and curing conditions. An overview of the state of the art on bio-based PU coatings and industrial implementation is summarized below.

Bio-based PU precursors

In a transition towards bio-based PU grades, a review on the major bio-based sources and industrially available components for the development of PU precursors was recently presented. On the one hand, several bio-based polyols are industrially available and derived from vegetable oils, carbohydrates, lignocellulose or proteins. On the other hand, the grades of commercially available bio-based poly-isocyanates remain limited, including e.g. pentamethylene-diisocyanate (PDI) and its oligomers, L-lysine ethyl ester diisocyanate (LDI); and a hexamethylene diisocyanate (HDI) allophanate combined with palm oil.

The bio-based di-/poly-isocyanates can technically be synthesized from amino acids, furan derivatives, carbohydrates (sugars), lignin-based aromatics, cashew nutshell liquid and vegetable oils as precursors. The synthesis of a bio-based PDI poly-isocyanate was patented (2015), forming an isocyanurate trimer with at least one allophanate group in addition. The PDI can be obtained by fermentative operation from lysine. Important parameters in comparing the coating formulations with PDI or HDI are the number of hydroxyl (OH) group containing groups intended for crosslinking of poly-isocyanates,. Particularly with increasing requirements regarding the robustness of a coating system in terms of weathering resistance, chemical resistance, high abrasion resistance, gloss retention and lightfastness, the coatings with high OH-group content and crosslinking density are favoured. Alternatively, the increase in OH-group content increases the polarity of the coating and affects water sensitivity.

Alternatively, the waterborne PU dispersions (PUDs) are mostly environmentally compatible products, since they do not contain or at least have low amounts of volatile organic compounds (VOC). The waterborne hardeners employ stabilizing agents in their structure in order to create good compatibility with PU dispersions in aqueous environment. The hydrophilization routes of polyisocyanates can either be done by addition of emulsifiers through a physical mixing or through the chemical modification and insertion of hydrophilizing groups in the molecular structure of the polyisocyanate.

The first route of emulsification may cause migration of the emulsifiers towards the coating surface with consequent loss in hardness and chemical resistance. Therefore, the anionically hydrophilized polyisocyanates are preferred and can be synthesized in combination with an ionic salt.

Potential of bio-based PU coatings

An assessment of bio-based PU coatings indicated that they have significant potential to be used as industrial products, with a partial or total replacement of petroleum-based PU, providing additional environmental benefits. In parallel, the variations in performance can also bring additional benefits of bio-based grades. It was claimed that bio-based diisocyanate synthesized from oleic acid and fatty acid diesters, which is a non-phosgene route, give PU with similar physical properties as PU derived from petroleum, and even higher tensile strength in some cases. The recent developments in synthesis of di- and poly-isocyanates from renewable resources mention that the final utility and value of these bio-based monomers can only be assessed by carrying out the detailed validation of specific end-user applications. For that, collaboration between industry and research institutes is imperative, in order to identify benefits in terms of unique and better set of properties and performance of bio-based coatings compared to existing commercial petroleum-based traditional coatings.

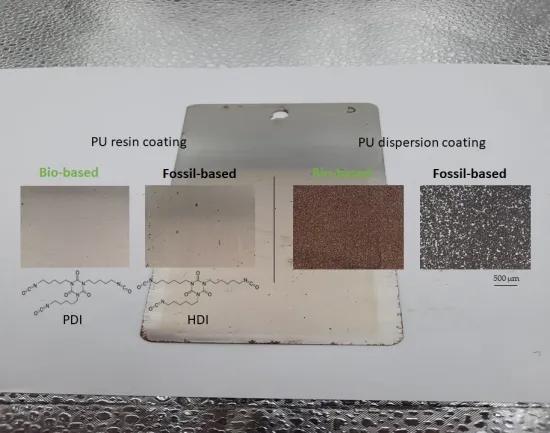

In recent research, the performance of an aliphatic isocyanate synthesized from crude oil (i.e. HDI or hexamethylenediisocyanate) was compared to an alternative hardener synthesized through fermentation of biomass (i.e. PDI or pentamethylenediisocyante). As the chemical structure of the bio-based PDI is slightly different, with an aliphatic chain of five compared to six carbon atoms, almost similar to better performance as a protective coating is demonstrated.

The application of bio-based PU coatings resulted in lower drying times and higher hardness with similar gloss, chemical resistance and mechanical resistance. In particular, the resistance of bio-based coatings after QUV-accelerated weathering testing was improved, owing to the better hydrophobicity of the bio-based PDI hardener. There was a positive gradual trend in performance with stepwise replacing fossil-based into bio-based content.

This study was performed as a demonstrator for the VLAIO-COOCK BioCoat project (2020-2022), with more information on this webpage. The study can be downloaded for free here.