Machining processes are the most common ways to produce a component or a part by removing excess material from a block of material. The quality of the part depends on how stable the process is. The stability and precision of the milling process are influenced by several factors. In this second article on machining dynamics, we focus on these factors.

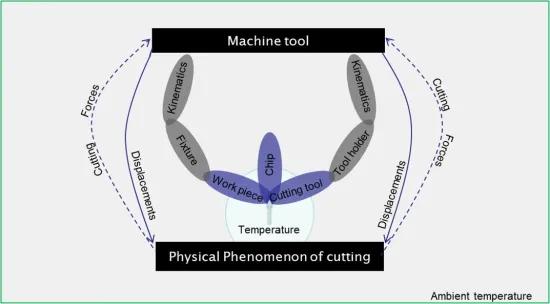

Mechanical parts that require high-accuracy and precision with a few microns are increasingly in demand within various industries such as aerospace, electronics, optics, communication etc. Though there are several advanced high-precision machines in the market today, in-depth understanding of the intricate relationships among machines, processes, tools and materials is indispensable for implementing high precision manufacturing. This understanding is also fundamental to control the quality of the surfaces and to handle geometric complexities that can come with these parts. This figure below illustrates the factors influencing the dynamics of machining process.

Factors influencing the dynamics of machining process

Influencing factors

The stability and precision of the milling process are influenced by several factors, some of them are listed below:

Machine rigidity and kinematics: The stiffness and stability of the milling machine affect its ability to maintain precise movements during the milling process. A machine that is not rigid enough may experience unwanted vibrations, leading to inaccurate cuts and reduced precision. The stability is also influenced by the kinematics of the machine tool as in how the axis movements are achieved. For example, having a fixed spindle axis can be more stable that a spindle with two axis movements.

Cutting tools: The quality and condition of the cutting tools used in the milling process also play a significant role in determining stability and precision. Worn or damaged tools can cause variations in the cutting forces, leading to poor surface finish and dimensional accuracy.

Cutting parameters: The cutting speed, feed rate, and depth of cut are important parameters that affect the stability and precision of milling. High cutting speeds and feed rates can cause excessive tool wear, while low speeds and feed rates can lead to a poor surface finish and extended machining times.

Workpiece material: The type of material being machined also affects the stability and precision of milling. Some materials, such as hardened steel or titanium, can be more difficult to machine, requiring higher cutting forces and greater machine stability to achieve the desired accuracy.

Fixturing and work holding: Properly securing the workpiece to the milling machine is critical for maintaining stability and precision during the machining process. Poorly designed or improperly installed fixtures can cause the workpiece to move or vibrate during milling, leading to inaccurate cuts and reduced precision.

Overall, achieving stability and precision in milling requires careful consideration of all these factors and their interaction with each other. Skilled operators and careful planning can help ensure the highest level of accuracy and quality in milling operations.

Online platform

On the 'modelgebaseerdbewerken' online platform you can already estimate the stability of different parameters of you process. You can also access models like milling economics model and use them to optimise your machining processes. Access to the platform is free of charge, but you need to register. You will also find the necessary explanations about working with the models on the platform, but be sure to keep an eye on the Sirris agenda because we will be organising both physical and online events like webinars and workshops.

Would you like to know more? Then get in touch with us!

The online platform is part of the COOCK project 'Model-based processing', which was launched with support from VLAIO.