The use of (real-time) data to adjust production processes - in machining the term is 'adaptive machining' - is the future of production. This is made possible by the increased availability of sensors. However, everything depends on having and understanding a standardised and structured model, in which the digital information is processed into a physical action. Such models are the key to successful digitalisation. In a series of blog posts, we highlight some basic models. In this seventh section, we will discuss how you can work with tool wear to optimise your machining processes.

Everyone talks about 'Industrie 4.0' or the extensive use of (real-time) data to adjust and control production processes as the future of production. Within the machining industry, adaptive machining has been talked about for years, and thanks to the increased availability of sensors, it is now within reach. However, all this depends on having and understanding a standardised and structured model, in which the digital information is processed into a physical action. Such machining models are available and are still being supplemented by new scientific insights. In industry, however, to some extent they have fallen into disuse. As they are the key to successful digitisation, we highlight some basic models in this series of articles. In this article: a punctual and structural approach to optimise machining processes by analysing tool wear.

Punctual approach

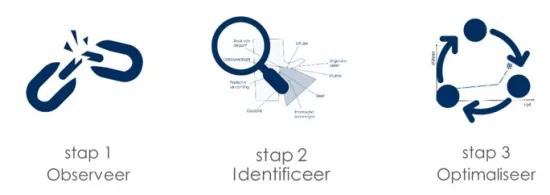

The type and amount of wear that occurs tell a lot about what actually happens during the machining process. Is there only frictional wear ('wear and tear') or are there also other phenomena such as chipping or crack formation? In the event of an acute problem, where machining is not running as planned, it is important to first thoroughly observe the wear formation. After all, chipping of the cutting edge can occur either immediately or only after a certain period of time. In the first case, the most likely conclusion is that the cutting conditions have been set too high, causing the cutting edge to break down immediately. In the second case, the cutting material can certainly also be questioned, as it may not be able to withstand the heat generated sufficiently and may beak down over time.

It is therefore important, in addition to proper observation, to chart the wear of the tools at several points in time. After thorough observation, it is possible to unambiguously identify the type of wear. (Online) catalogues of tool suppliers often contain tables with examples for comparison, and an overview page is also provided on our online platform. Such tables also contain the necessary guidelines to avoid or minimise the identified form of wear.

Structural approach

Of course, you don't have to wait for a problem with a machining process to make use of information from tool wear. The objective of the structural approach is to identify improvement paths through the analysis of the occurring tool wear.

Firstly, the scope of the analysis is defined: does it look at a specific operation or machine or, more generally, at the entire milling or turning department? Once this is established, the tools used or consumed are collected for a certain period, depending on the intensity of tool use. To identify meaningful improvement paths, you need to collect at least 100 used tools per operation.

In a second phase, the wear and tear on each tool will be identified. Since there are no acute machining problems, the primary form of wear will be friction or wear and can also be dimensioned. This provides a graph showing the distribution of wear across all tools, which is the basis for analysis. Is the majority of the wear against the limits (rule of thumb: 300 µm for fine, 500 µm for roughing), then the tool is used correctly. If the wear is systematically far below these limits, the tools are not being used to their full potential.

In the case of cutting plates, it is also possible to analyse whether all cutting edges are actually used. Or the process-parameter or tool life can be plotted with it, in order to get an indication of the machined volume per tool as a function of wear. The analysis then leads to the possible improvement paths: optimising the cutting conditions of a certain process, providing training on the use of certain tools, etc.

Structural studies that we have carried out in various companies show that tools are often thrown away too quickly. After a short training course and increased attention, savings of 5 to 10 percent of the total annual tooling costs were soon achieved.

Online platform

On the online platform 'modelgebaseerdbewerken.be', you can consult various models and use them to optimise your machining processes. Access to the platform is free of charge but you do need to register.

On the platform you will also find the necessary explanations on how to work with the models, but be sure to keep an eye on the Sirris agenda, as we will be organising both physical and online explanatory sessions.

More info? Please contact us!

The online platform is part of the 'Model-based processing’ COOCK project that was started with the support of VLAIO.