We share the key lessons and insights from our sessions at the CE Connect learning network with you. In the most recent session, we explored how you can build a new ecosystem of actors: where to start, how to find the right partners, why they should cooperate, how to start cooperating. For these and other questions, we managed to define actions that will lead you to meaningful answers.

The study of ecosystems, for Maastricht University provided the insights, reveals three major basic elements for circular innovation: cooperation, experimentation and building/expanding platforms. Actions based on these three elements allow actors to derive maximum value from products, components and materials, while minimising the absolute use of materials.

Role of platforms

We have previously pointed out the need for cooperation, the (small) step-by-step approach and the setting up of (simple) experiments. However, the role of platforms has not explicitly been highlighted so far. In this context, we see platforms as common information and data transfer tools, across the value chain or ecosystem. In many cases, the need for information and data sharing quickly becomes apparent. For example, information about product use (location, status, availability and composition), which was also discussed in Circular Bytes. If the right actor has the right data available (e.g. remanufacturing has data on usage intensity), the process will be steered towards optimal value retention. One example may be the remanufacturing or reuse of components. In other cases (e.g. B2B of production machine) this is less obvious. In these cases, too, platforms are aimed at optimising value retention. For a number of actors in such a context, not data, but the optimisation of business processes may be the lever (easy access to service, use of shared capacity, fast adaptation of production capacities/ qualities in function of changing needs, availability of upgrades, etc.)

Although setting up such new value chains does not require specialised knowledge, there is a need of some structure and logical steps or phases that can be completed iteratively. Recognising the most important preconditions in the exploration and realisation of such a new ecosystem can be of great added value. Sirris and Agoria have developed tools to support you in this process, e.g. the circular-systems-canvas. This tool will also be refined, step by step, based on user feedback.

Know thyself

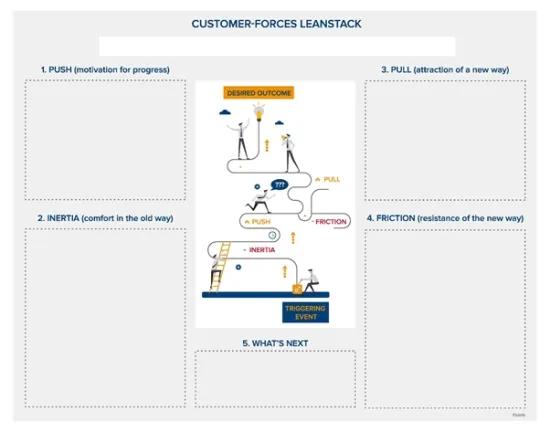

The testimonies of Atlas Copco (Mobile air) and JuuNoo confirm that the focus is initially on learning and understanding. In this first phase, you explore the limits of your knowledge. A rough sketch of your company's products, services, etc. can be a first step. It will make it clear that hardly any actors in the chain know the whole chain. That is reassuring. Not knowing together is not as bad as not knowing alone. It forms a basis for humble, open discussions with other stakeholders. A useful tool is the previously mentioned Customer Forces Lean Stack.

One thing is certain, we soon run up against the limits of our knowledge and understanding of the other parties in the picture. The way to do something about this is to go out and talk to the players in the ecosystem. Not to sell something, not to do business or steal knowledge, but to learn, to understand what others are struggling with, to explore common (circular) goals.

Such a common goal is the key to giving a working ecosystem a chance to live. This is the core of the circular-systems concept that was tested in this session on the Atlas Copco case.

Case: Atlas Copco

Atlas Copco (Portable air) ondesigns and markets mobile compressors. One product group consists of 'small' compressors, which are used on construction sites. These have a relatively low running cost and are used 'infrequently'. Another product group refers to compressors for geothermal and other soil drilling activities, which are much larger and heavier and are used very intensively (in continuous operation). Atlas Copco aims to significantly reduce the environmental impact over the entire lifecycle of both product groups. An approach per product group is therefore necessary. A number of insights have been gained by mapping out the current value chain, whereby the actors and goods flows are mapped out from supplier to product discard (including recycling or reuse). Incentives for remanufacturing (retaining ‘old’ combustion engines) may be counterproductive to achieve the intended circular goals (engines with higher emissions stay in service longer). Also, the knowledge of how and why the other actors in the chain sell, dispose of or scrap the compressors, etc. is very complex. Perhaps most of the actors in this ecosystem also have circular goals (explicit or implicit), but coordinated they can realise a greater impact. Even though Atlas Copco has remanufacturing activities (also for old models) and is active in the purchase and sale of refurbished products, they are also dependent on the interests of other stakeholders. The next step is to investigate these interests. This requires entering into open communication with the stakeholders and looking for ways in which they can reinforce each other.

Case: JuuNoo

JuuNoo is a young company (active for three years) which designs, produces and markets interior walls, based on a deep awareness that fast and therefore scalable products and services are needed to meet the ambitious circular (and environmental) challenges.

As a start-up company, it is aware of its limited knowledge and understanding of the market and its processes. For this reason, the company has put a lot of effort into open learning-driven discussions with a whole range of actors in the sector. JuuNoo did not start from a schematic representation of what it thought the construction world looked like. It started from an eagerness to learn and humility and gained insights through ‘problem interviews’ (based on Customer Forces Lean Stack). These mostly open contacts have allowed it to find its place in the market. More than that, it has been able to identify and solve real customer problems. JuuNoo does not sell ‘circular products’, it sells high-quality walls that can be installed and removed quickly (and with minimal waste) at a competitive price. It also provides a buy-back guarantee, whereby the buyer knows in advance what the residual value will be. The common goal in this network is therefore speed (almost no waste) and the potential for reuse and resale. JuuNoo defines its circular yardstick (focusing on its product-service) as the residual value of the product divided by the cost of disassembly, on which they score particularly high compared to other wall systems.

Interested in being in the front row of one of our learning networks and getting more detailed information on such cases? Make sure to let us know! We will get in touch and together see which network is most suitable for you.