Due to developments in data-driven algorithms, more and more AI tools are being developed to process images. Supplying images of tools to AI models can automate this inspection process. The first steps in this direction have been taken in a recent research project.

In a traditional machining environment, an important aspect is inspecting tools for wear and tear. As soon as the tool appears to be too worn, the quality of the end product can be compromised, there is a risk of vibrations and/or the tool may collapse completely (breakage). This control typically takes place in two ways in production today: through experience and regular changes (whatever degree of wear there is) or through a quick visual control (with the naked eye or with a microscope). The latter is more accurate, but takes time and leaves room for interpretation errors. The former results in inefficient use of tools and higher production costs.

Due to developments in data-driven algorithms, more and more AI tools are being developed to process images. Supplying images of tools to smart algorithms can automate this inspection process. This would allow (in the long run) for a camera to be built into a machine, a tool to be brought to the correct position by the spindle, where a picture is taken and this is then automatically analysed. If the calculated wear is below certain limits, further milling can be carried out, otherwise a tool change must be carried out.

'Pixel analysis'

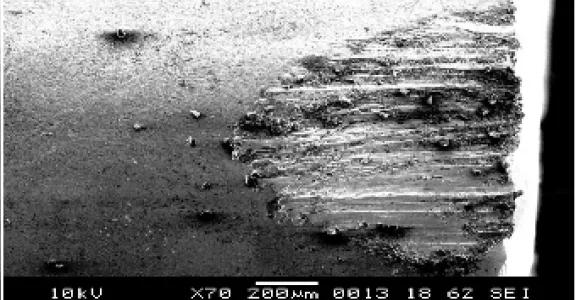

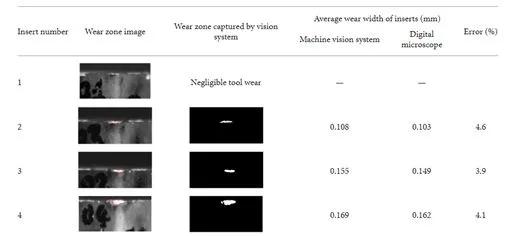

Recently, research work was published - ‘Measurements of Tool Wear Parameters Using Machine Vision System’ by A. Thakre, A. Lad and K. Mala (2019), in which an algorithm was set up using ‘pixel analysis’. Based on a simple Sony camera of a few hundred euros, and LED lighting, images were made of cutting plates of worn tools. The images were processed using an algorithm. Via the grey values and different thresholds, different values of wear (maximum wear, surface,...) could be calculated using a script written in Matlab. This was then compared with analyses using the microscope and revealed an average deviation of barely 3 percent over 12 tools.

(Source pictures: ‘Measurements of Tool Wear Parameters Using Machine Vision System' door A. Thakre, A. Lad en K. Mala - 2019)