Vandewiele NV, a well-known weaving machine and textile system manufacturer, studied the options to implement laser curing to increase the quality of the machines and, at the same time, shorten the turnaround time.

Vandewiele NV in West Flanders is the market leader in design and manufacture of high-tech machines and solutions for the textile industry. Vandewiele makes machines for the complete production process, from yarns to the final finishing of textile products.

The manufacturer reached out to Sirris to research whether integrated laser curing would increase the sustainability and quality of their machines and shorten the turnaround times of component production.

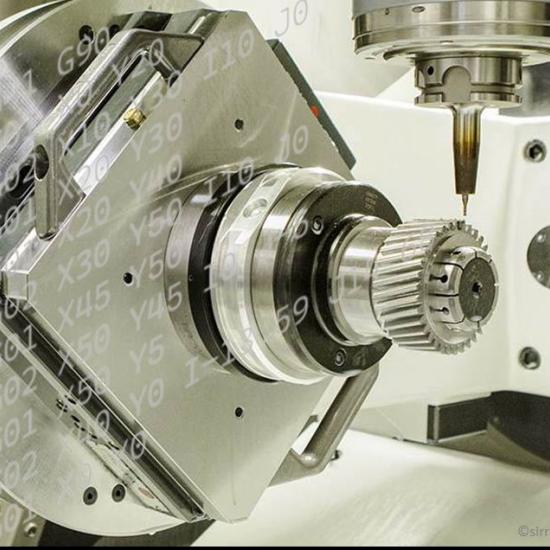

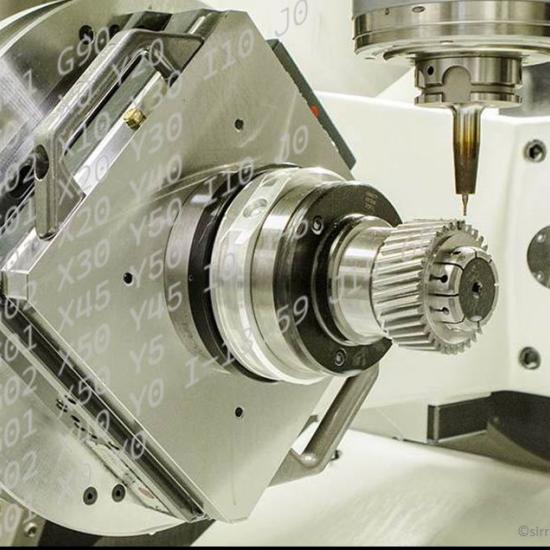

Three subsequent feasibility studies

Three cases were selected to study the feasibility of this technology. This ensured that the hardness could be compared to that of traditional curing methods and some production steps could even be skipped therefore decreasing the costs for the manufacture of the component.

The study showed that smart thermal modelling of the laser-curing process combined with knowledge of the material led to good results based on a small sample quantity. The hardness increased up to 61.5 HRC compared to 58 HRC when applying traditional curing methods.

Vandewiele NV is now studying the application of this and other technologies within their company in Belgium.