An overview of all the information you need

Do you want to explore the potential of ReX (reuse, remanufacturing, refurbishment, repurposing) for your business? Make sure to collect information on the condition of incoming products (cores) and their components after their first period of use. It will help you understand your options and reduce any risks or uncertainties. This may include:

- The installed base of products you have access to: product types, versions, any modifications, number, location, duration of use ...

- Degradation: how and where do products and components degrade, and what is the impact on their functionality, remaining lifespan and residual value?

- What are the variations in degradation of products and components, and which parameters have the greatest influence on them?

- Which ReX concept has the most potential for my business context? Is it better to reuse, repair or replace certain parts?

- What actions (interviews, experiments, calculations) are needed to gather crucial information, assess and reduce risks, and make good ReX decisions?

Overwhelmed? Don't panic: an important part of this information may be at your fingertips. It pays to check what useful information you have easily available.

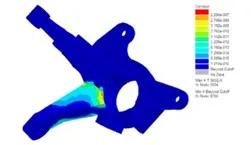

Information from product development, engineering and R&D

In the design process, colleagues do their best to make the product meet customer needs, provide usage context and objectives in terms of functionality, reliability, safety and longevity. In doing so, they typically gather a lot of information on how the product may be used and "loaded" (e.g. mechanical load, number of use cycles, exposure to temperature, moisture, water, chemicals, etc.), the associated degradation mechanisms (e.g. breakage, wear, fatigue, corrosion) and their impact on functionality, safety, desired maintenance and service life.

This information can be contained in different activities, sources and carriers:

- Specifications (requirements), product specifications, quality requirements

- Calculations, models, simulations, FMEAs (Failure Mode and Effects Analysis)

- (accelerated) degradation testing, functional testing

- Improvement projects (problem solving, redesign)

Information from maintenance and repair

Colleagues who maintain and repair products and offer related services may also have a wealth of information. In fact, they continuously collect real-world data on the functioning, degradation and recovery of your products:

- Insights on degradation in practice: occurrence (frequency), location (which components, which place), causes (key parameters and root causes for degradation) and the typical wear parts, which are best replaced anyway.

- Historical data on spare parts sales

- Best practices and experience in inspection and NDT (non-destructive testing) of products and components

- Controller and sensor data on performance, load and usage history, failure modes, etc.

- Repairs: approach and process, time needed, expertise, resources and cost (service records)

Information about the product’s use phase

Also be sure to check what information on the installed base of products and their use phase already exists in your company or with your partners. A few examples:

- Your ERP system: the unique product identification (nameplate, barcode, serial number) can give access to a lot of data on product types, versions, age, service records, etc.

- Product passports

- Data from controllers and sensors: sometimes you have direct access; in other cases, you can request this data from partners such as dealers, installers and integrators.

Information about market demand

Before you invest in the ReX of a particular product, you should have a clear picture of the market demand and the potential customers or customer segments. Is there (still) enough demand for this type of product? Do they meet customer expectations and current regulations? What are customers willing to pay for this? Is there potential to tap into new customer segments?

These data can be of use:

- Historical sales data (e.g. in your CRM system)

- The market intelligence of your marketing and sales teams

- The knowledge in your legal team: what is the (current and future) evolution of the regulations linked to your product (e.g. Ecodesign Directive)?

- The ReX offer of your product (type) on the internet: search, for example, ‘used product X’, ‘remanufactured product X’, ...

Conclusion

Exploring the possibilities of ReX for your business doesn't have to be overwhelming. You may already have a lot of information - or the right people - to determine the condition of cores and their components.

In a subsequent blog, we will discuss how to tackle the inspection and NDT (non-destructive testing) of your products.

Remanufacturing: would it work for your business?Reuse, repair, upgrade ... Remanufacturing is just one of the possibilities. How can you be sure you are using the most appropriate strategy for your business? With the COOCK project 'CIRKEL - Remanufacturing as a lever for value creation in a circular manufacturing industry', supported by VLAIO, Sirris gives you the practical tools you need to mitigate the risks and increase the chances of success. This is how you can get started

|